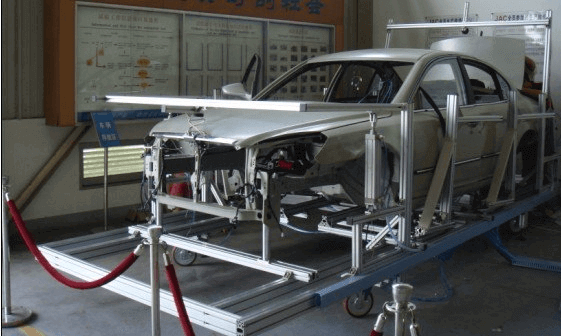

We have seen that engineers place a great deal of importance on CNC machining in fields where extreme accuracy is required, such as the aerospace, robotics, and medical industries.

However, a variety of other industries, including the following, also use it:

- Electrical

- Defence

- Mining

- industrial equipment

- Automotive

- Agriculture

In essence, the possibilities for CNC machining are endless! CNC can be the best option for you if you require an item created precisely or in big quantities (for a prototype or for production).

We take great pride in providing CNC machining skills for such a huge variety of sectors. We have witnessed firsthand how helpful skillfully CNC machined parts can be for practically any and every industry, from aerospace and energy equipment to electronics and automobile goods.

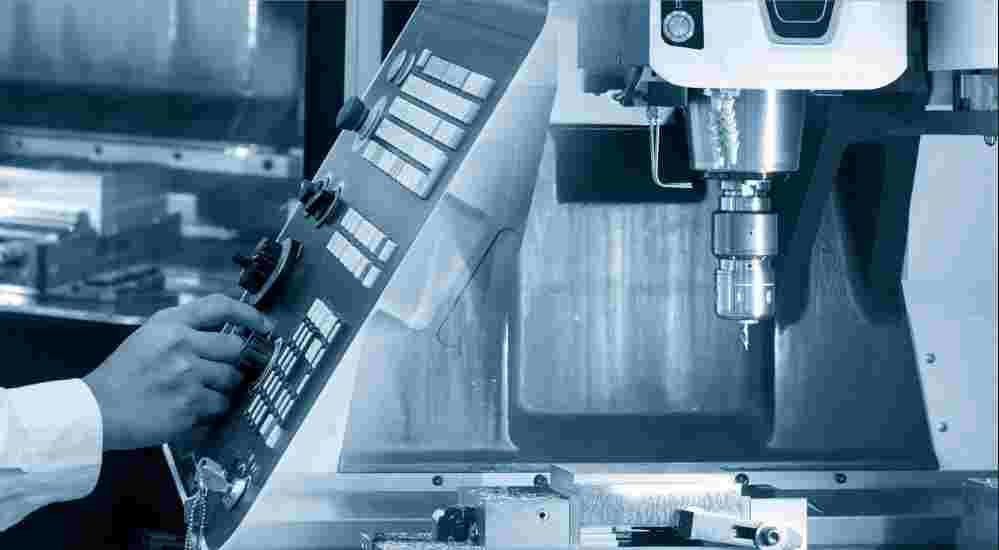

How Do CNC Devices Operate?

A CNC machine executes instructions from computer software that has been pre-programmed. To produce a particular material shape, this program describes the machine’s speed, movement, and position.

The steps involved in CNC machining are as follows:

1. Using computer-aided design (CAD) software, the designer produces a 2D or 3D drawing. This file contains instructions for the CNC machine on how to make the part, such as the structure and dimensions.

2.Converting the CAD file to CNC code: The designer must transform the CAD drawing into a CNC-compatible file because CAD files are used in numerous applications. With the use of a program like CAM software, they may convert the CAD format to a CNC format.

3.Setting up the machine: After having a file they can read, the operator can configure the computer itself. For the software to run properly, they attach the proper tools and workpieces.

4.Process execution: With the machine and files ready, the CNC operator can carry out the last step of the procedure. They launch the program, which then controls the machine and leads it through each step.

The CNC machine may work effectively and precisely when the designer and operator follow this procedure exactly.

What Benefits Do CNC Machines Offer?

1. High accuracy

Precision is one of the main advantages of using CNC machining over manual processes. Without a competent operator’s constant supervision, it is feasible to produce parts that adhere to exact specifications.

High-precision CNC machined components are essential to the aerospace and defense industries. The ability to produce such exact components in accordance with specifications may save lives.

2. Stamina

One of the key benefits is the ability to run CNC machines 365 days a year, 24 hours a day.

3. Productivity

Production can begin once the operator has programmed the machine with the required design criteria. It takes no time at all to produce parts once the CNC machine has begun a manufacturing cycle.

4. Strengthened Abilities

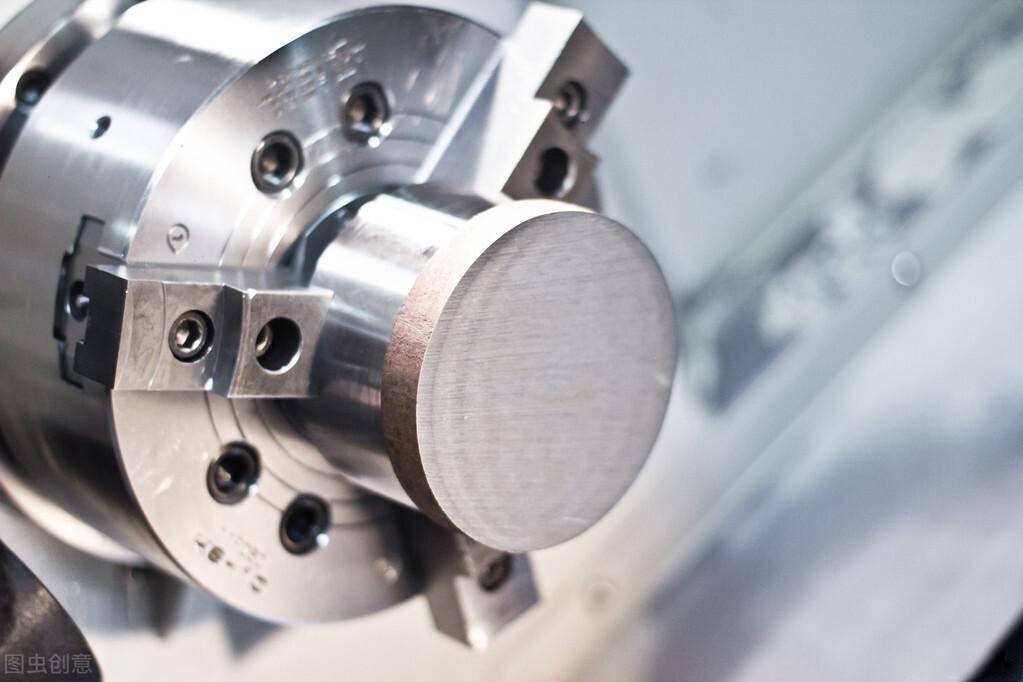

A spinning carousel that can hold up to 30 tools is typically found on a CNC machine. While milling and machining, these tools can be automatically changed out.

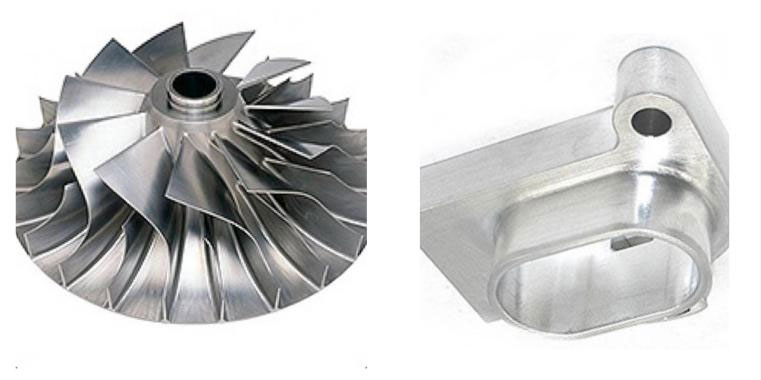

Complex shapes are produced by CNC milling machines with advanced design software that are impossible for manual machines to match.

5. Wide Range of Supported Materials

A variety of materials, including composites, metals, rigid foam, carving foam, phenolic materials, and plastics, are compatible with CNC machines.

6. Reliance on Human Labor is Reduced, and Human Errors are Reduced

CNC machines are self-contained, precise turning machines. There is no need for manual intervention, eliminating the chance of mistakes made by people.

7. Reduced Prices

A CNC machine may have a high initial cost, but its lower ongoing costs more than make up for it. CNC machining is economical because to its high output rate, low error rate, and affordable production expenses.

8. Increased Security

A CNC machine’s only interactions with an operator are for programming and upkeep. The rest of the procedure is fully automated. Operator safety is increased because they are not need to be close to the cutting equipment.

9. Minimal Upkeep

Because CNC machines require less maintenance and can be serviced internally without the use of maintenance specialists, they are cost-effective.

JTR is a Chinese manufacturer specializing in CNC machining services. We have many years of experience in this field. We hope that customers at home and abroad who need CNC machining services can inquire from us at any time.