“Made in China” has been associated with inexpensive manufacturing for the last twenty-two years. In the wake of the global supply chain reconfiguration and the advent of automation, productivity has spurred a host of new inquiries amongst businesses:

Is China’s CNC machining service still cheap today?

The answer is yes — but not in the way it used to be.

In 2025, China’s edge has shifted from low wage workers to the ability to greatly enhance the supply chain with optimal production efficiency from state-of-the-art factories with the best processes. In terms of pricing, quality, and service, China earns great value with world-wide clients.

Where Does “Cheap” Actually Come From?–A Quantified Look at China’s Cost Advantage

Cost Comparison: China vs. Other Regions

While appraising CNC machining costs, including labor, material, overheads, shipping, and taxes, there is still considerable advantage to be gained from China:

| Region | Average CNC Machining Cost (per part) | Compared to China |

| Western Europe / North America | 100% baseline | +40%–60% higher |

| Mexico | 80%–85% of Western cost | +20%–30% higher |

| Southeast Asia (Vietnam, Thailand) | 70%–80% of Western cost | Similar or slightly higher (within ±10%) |

| China | 100% reference | Baseline |

- Automation & productivity: Due to the ongoing use of 3-, 4-, and 5-axis CNC centers equipped with night-shift automation and MES-driven scheduling management, productivity is rising and efficiency is improved.

- Raw material supply: Bespoke suppliers of aluminum, stainless steel, and titanium reduce costs and lead times.

- Cluster efficiency: In clusters like Shenzhen, Dongguan, and Ningbo, machining shops, anodizing companies, mold makers, and logistics service providers work within a few minutes of each other.

- Scalability: Due to China’s industrial base, prototyping and mass production can be achieved within a short time and at a constant cost.

In short, “cheap” in China today is not a race to the bottom — it’s the economics of scale and efficiency that few regions can match.

Cheap ≠ Low Quality: Understanding Hidden Costs and Real Value

The Real Concerns Behind Low Prices

“Low cost” brings the following to the minds of Western purchasers:

- Quality Issues

- Missed Deadlines

- Issues With Communication

- IP Threats

- Lack of Post-Sales Customer Service Support

Most of these concerns are due to the 2000s. Unlike back then, now, the best manufacturers from China work under internationally accepted standards as well as open structuring.

The Hidden Cost Equation

| Potential Hidden Cost | Modern Mitigation in China |

| Quality risk | ISO9001, IATF16949, full inspection with CMM and SPC systems |

| Communication | English-speaking engineering teams, real-time project management tools |

| Lead time | 24-hour prototype machining, in-house finishing |

| IP protection | NDAs, restricted data access, separate production lines |

| After-sales | Root-cause reports, continuous improvement tracking |

Considering Time, communication, logistics, etc., and rework, many companies calculate China’s effective total cost in the range of 20-40% lower than local alternatives, even when the quote price variance seems smaller.

“Cheap” therefore means high efficiency and predictable outcomes, not “cut corners.”

When China Is the Best Choice for CNC Machining

Ideal scenarios:

- Prototyping to small-batch production(50–10,000 units)

- Projects with multiple materials, aluminum, steel, and auxiliary plastic components, within the same assembly

- Business opportunities with fast turnaround and tight deadlines

- Parts with medium precision engineering (±0.005–0.01 mm)

- Engineering and design iterations are provided by the supplier.

In these cases, both cost and agility are critical to the startup and R&D-driven companies. logic.

These days, a lot of Western countries’ Original Equipment Manufacturers (OEMs) mistakenly view China as exclusively a base for rapid product validation and pilot runs, regardless of where the final mass production will take place.

When China Might Not Be the Optimal Choice

While China offers remarkable value, it’s not always the right solution.

Less suitable scenarios

- Ultra-precision parts (aerospace, semiconductor tooling) modules needing onsite supervision

- Defense or IP-sensitive parts with legal data localization

- Large or heavy parts for whereby international freight is deemed more expensive than the value gained

In all such scenarios, domestic or near-shore machining may turn out to be more viable, in fact.

The smart decision is not “China or not,” but when and how to use China strategically within a global supply chain.

Trends & the Future of CNC Machining in China

China is doing something new and interesting with CNC machinery.

- The use of IoT sensors and Artificial Intelligence, which promptly inspect work, is having an influence on the next stage of ”smart manufacturing,” as is the application of digital twins.

- There is the growing use of automation and robotics, with unmanned machining cells in operation around the clock.

- There is also “green production” with the tracking and reduction of carbon emissions to EU/US sustainability standards.

- The “contract manufacturing” model is changing to “engineering collaboration” with the provision of DFM (Design for Manufacturing) and product optimization services.

The future of “cheap” will be defined by intelligence, not labor — and China is investing heavily to stay ahead.

What JTR Machine Can Do for You

In the long run, deciding on suppliers falls on the issue of both trust and skill, not on estimates alone.

Leading the industry, JTR appreciates the value of both business and engineering and provides professional and reliable CNC machining services.

Our Capabilities Include:

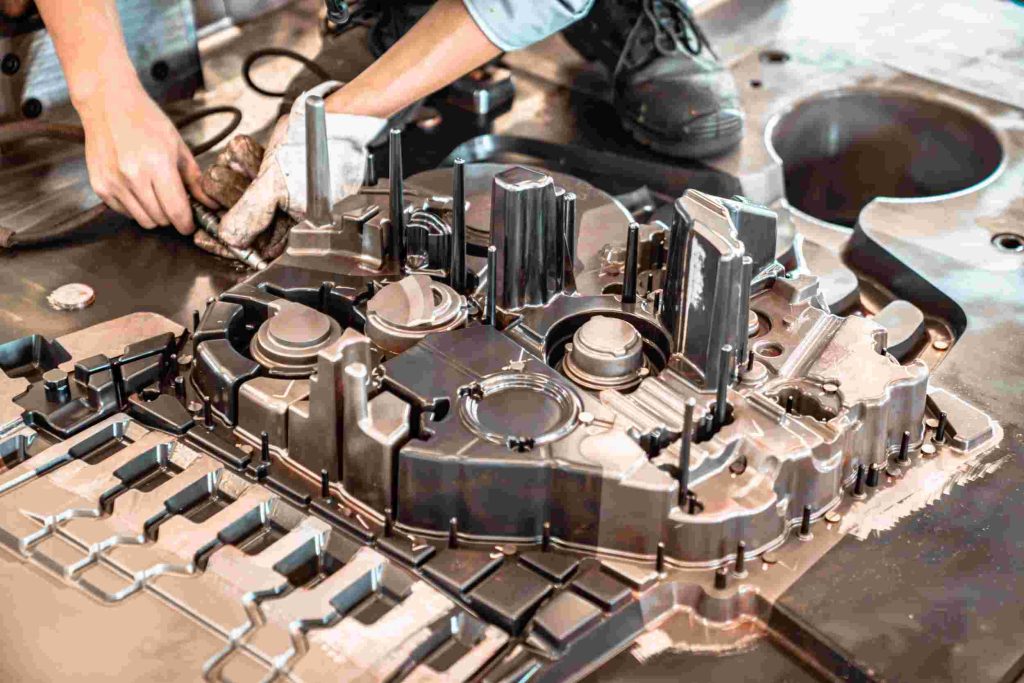

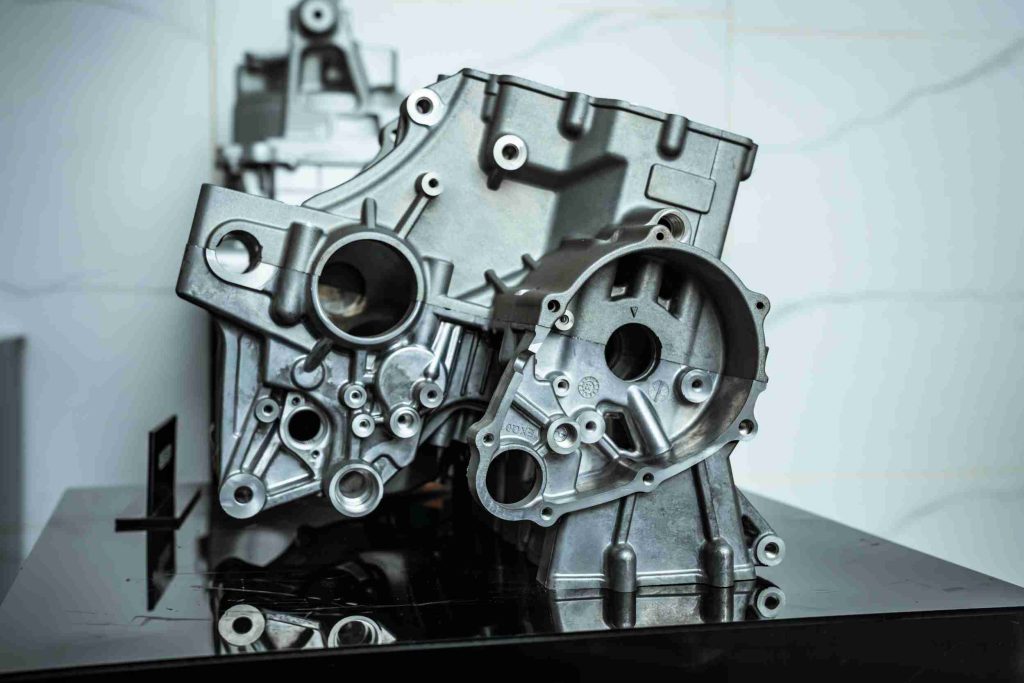

- A CNC Machining Process Utilization: For highly accurate metallic and polymer components, 3-, 4and 5-advanced machining centers are utilized.

- A Machining Capability: Every 0.005 mm tolerance level is considered and maintained.

- Available materials: Aluminum, stainless steel, POM, ABS, titanium, copper, brass, and even lots more.

- Surface finishes: Bead blasting, anodizing, phosphate coatings, polishing, and even electroplating.

- Assured quality: ISO-certified work, verified inspection reports, CMM measurements.

- A lead time: For prototypes, it is 3 days, and there is stable mass production delivery thereafter.

- Pricing: Good prices, competitive quotations, transparent pricing policies, and flexible minimum order quantities are offered.

If your goal is to balance cost, quality, and speed, JTR can help you achieve the best total value for your CNC machining projects.

Final Thoughts

China has one of the best values in the world for CNC machining. It is not the cheapest place, but it offers the best service for the money.

In 2025, the real question is no longer “Is China cheap?”

It’s:

“How much value can you unlock when you partner with the right Chinese manufacturer?”