As an example, consider aerospace engines: include components made of titanium with complex contoured surfaces and precision milled pockets interlaced with turned profiles. 10 years ago, manufacturing such a part would have required a lathe, turned rotary block, and a milling machine, each with a separate alignment. The numerous setups, combined with clamping, contributed towards a considerable amount of idle time, along with introducing multiple error sources.

These barriers have been addressed by integrating CNC milling and turning with the use of multi-axis and mill-turn machines. 4 and 5-axis CNC machines, equipped with turntables, have advanced from performing sequential tasks step by step to multi-process integration. Leading this revolution in technological advancement and quality is the CNC machine services for volume production.

What are the Core Technicals of Multi-Axis and Mill-Turn Machining?

From discrete to integrated has evolved in the way CNC milling and turning work now, in comparison to before.

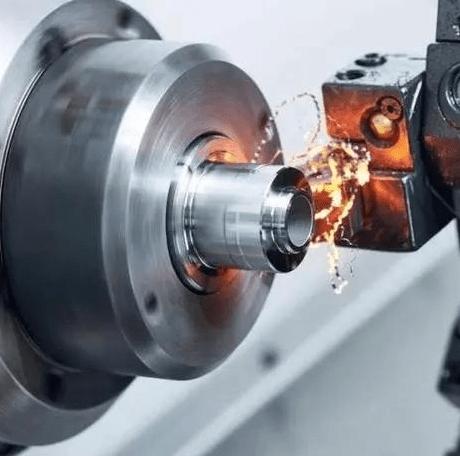

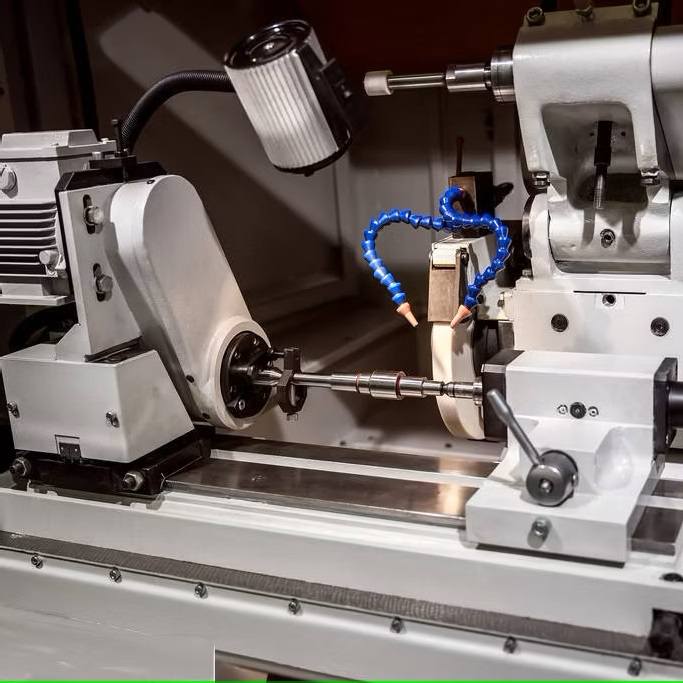

As previously used, turning and milling have always been separate, where turning simply means rotating the workpiece against a stationary tool, and milling is rotating a tool against a stationary workpiece. The mill-turn center is slowly erasing these concepts. These machines work as hybrids that perform both operations fully automated without the operator needing to touch the part. The rod is held in a rotating spindle, referred to as the C-axis, while the milling spindle has the ability to approach the rod freely without rotating the spindle. Often, the spindle is tilted, referred to as the B-axis. This enables an environment of complete machining in a single setup.

The Advantages of CNC Turning and Milling Convergence

As integrated, the list of improvements gained is as follows:

- Reduced Error Margins: All error tolerancing is eliminated by performing the part within a single clamp. This applies to any situation where a workpiece is passed over for separate operations on a lathe and a milling machine. This is true for the medical and aerospace industries, where accuracy on the order of micrometers is absolutely vital.

- Significant Productivity Improvements: The setup process used to take hours or even days, spread across multiple machines. Now, we can get it done in just minutes. This is a game-changer—it dramatically cuts down our lead time and gets our products to market much faster.

- Unmatched Flexibility: You can create really complex shapes like undercuts, spirals, and curved designs—plus even more that you might think of—using five-axis milling and turning. Trying to do this with traditional three-axis machines just isn’t cost-effective.

- Increased Machine Length: Investment in more complicated machinery like 5-axis milling (and turning) is highest; however, its use greatly reduces the total machine, fixture, labor, and lead time costs, resulting in a lower total cost per part. This is especially true for more complicated components.

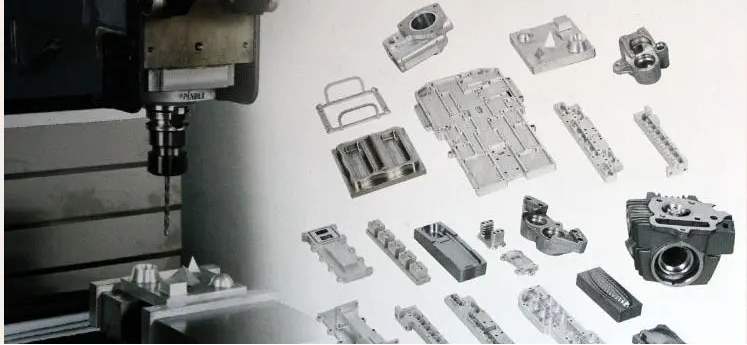

Common Applications of CNC Turning and Milling Convergence

The true power of multi-axis and mill-turn machining is realized in its application across high-stakes industries, where complexity, precision, and reliability are non-negotiable.

- Aerospace: Industries such as manufacturing turbine blades and ship engine impellers rely on machine parts. Engine turbine blades and impellers are made of complex materials such as titanium and chromium-nickel-iron alloys. Each blade is made of a single block.

- Medical: This industry requires complex surgical tools as well as custom implants, such as spinal cages and skull plates. These life-saving components are made of titanium or PEEK and meet surface standards that are crucial to the body.

- Automobiles (high-performance and EVs): The application range of milling rotation centers extends from lightweight structural components of electric vehicles to complex turbocharger rotors, where a balance between rotation and blade feature milling is required. These machines are crucial for the mass production of complex, robust, lightweight and precise components, which can expand the application range of vehicles and enhance the efficiency of engines.

- Telecommunications and electronics: Precision waveguides and the enclosures of 5G base stations are the main examples. These components often mix and grind the external casing with the delicate rotating internal connections and heat dissipation channels. The milled housing and rotary connector ensure that the unit adheres to electromagnetic shielding, thermal management and signal strength in a single, robust unit.

Why Choose China CNC Machining Service?

Understanding The Modern China CNC Machining Factory

People have known for a long time that Chinese manufacturing is only about being cheap and low-tech. These days, a CNC machining factory in China is more like a tech center. They have some great local brands as well as top-of-the-line multi-axis and mill-turn machines from big names like DMG MORI, Mazak, and Hermle. Skilled engineers and programmers who are great at improving processes, planning tool paths, and understanding materials run this hardware. Also, following international quality standards like ISO 9001, AS9100, and IATF 16949 is pretty common these days. This helps us make sure that what we make is always the same and works.

The Unique Edge of a China CNC Machining Service

The real power of a China CNC machining service goes beyond the machines it has. It is the best manufacturing ecosystem.

- Supply Chain Convenience: Being close to suppliers of raw materials, cutting tools, and tooling means faster response times and lower material costs. A specialty aluminum plate or carbide end mill that you need is often only a few hours away.

- Collaborative Manufacturing: Top CNC machining factories in China usually do not work alone. They usually offer a bunch of services in one place, such as CNC machining, sheet metal processing, mold making and various surface treatments (such as anodizing, electroplating and painting). This is very convenient for customers because they can complete all the work under one roof. It really simplifies logistics and makes things accountable.

- Scalability and Flexibility: These places are really great at handling the entire product journey, from quick prototypes and small batches to big production runs. They can easily adapt to whatever each project needs.

Future Trends and Conclusion

The future of manufacturing is all about being smart and connected. More and more Chinese machining centers are jumping on the Industry 4.0 bandwagon, using AI for things like predictive maintenance and optimizing processes, plus they’re setting up automated robotic cells for lights-out production. The next big thing? It’s the mix of additive (3D printing) and subtractive (CNC machining) manufacturing happening on one platform, and some trailblazing factories in China are already diving into it.

In conclusion, bringing together CNC milling and turning with multi-axis and mill-turn technology isn’t just a small step forward; it’s really setting the stage for high-quality, precise manufacturing. The CNC machining service in China has not only recognized this reality but has also tapped into its strong ecosystem, major tech investments, and growing know-how to position itself as a key player that’s reliable and sophisticated on the global stage. For any business looking to tackle the challenges of modern manufacturing, getting familiar with and engaging in this advanced capability isn’t just a choice anymore—it’s become something you have to do strategically.