What is the CNC fixture in CNC machining? And how are you supposed to use it? In this article, you’ll discover what are jigs as well as fixtures and exactly how they are used? as well as meaning, Parts & different types of jigs and also components with their working concepts.

Against this, a capstan and turret lathe can be quickly adapted for repetition service account of the multi-cooling plan and use transverse quit this raises the rate of production.

Nevertheless, every type of item can not be machined on a capstan or turret lathe and also might involve making use of boring, milling, preparation as well as grinding equipment, etc. If such items are to be created in identical shapes and sizes on a mass range, appropriate gadgets have to be utilized for holding as well as situating objectives to ensure that the repeating job can be done. These tools are the jigs as well as components.

What is Jig?

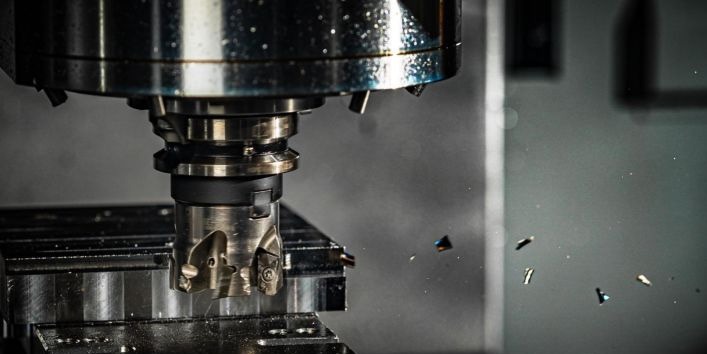

A jig might be defined as a gadget that holds and also situated a work surface as well as overviews and also controls several cutting devices. The holding of the work and also leading of the tool is such that they lie in true placements relative to each other.

In building, a jig consists of a plate, a structure, or box constructed from steel or in some cases of non-metal having stipulations for managing the elements in the same positions together, and after that guiding the device inaccurate positions on the operate in accordance with the illustration, requirements, or procedure layout.

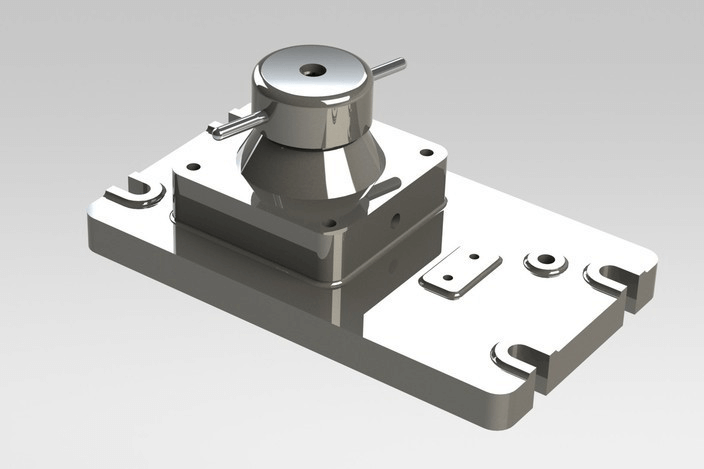

What is a CNC Fixture?

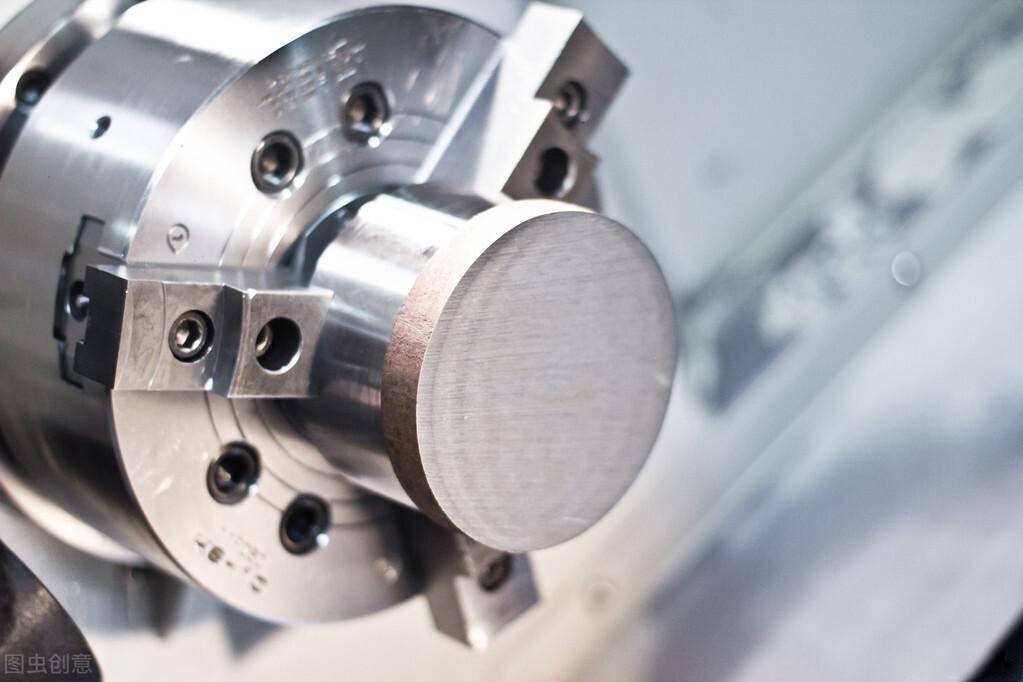

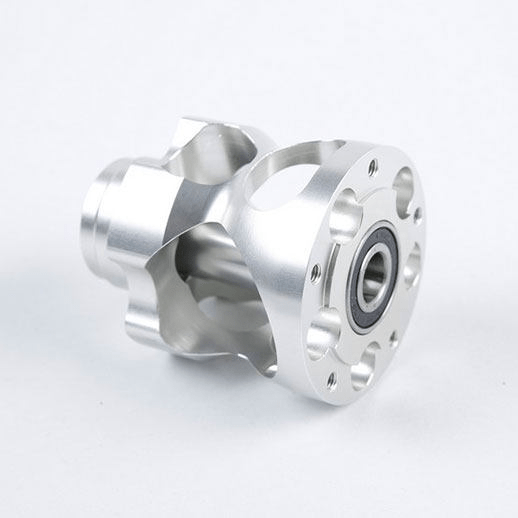

A fixture is a device that holds as well as finds a work surface during an inspection or for a production procedure. The fixture does not guide the tool.

In building and construction, the component comprises a different standard or particularly created job holding the gadget, which is clamped on the equipment able to hold the work in the placement. The devices are evaluated the needed settings on the work by using assesses or by manual adjustment.

Jigs as well as Fixture

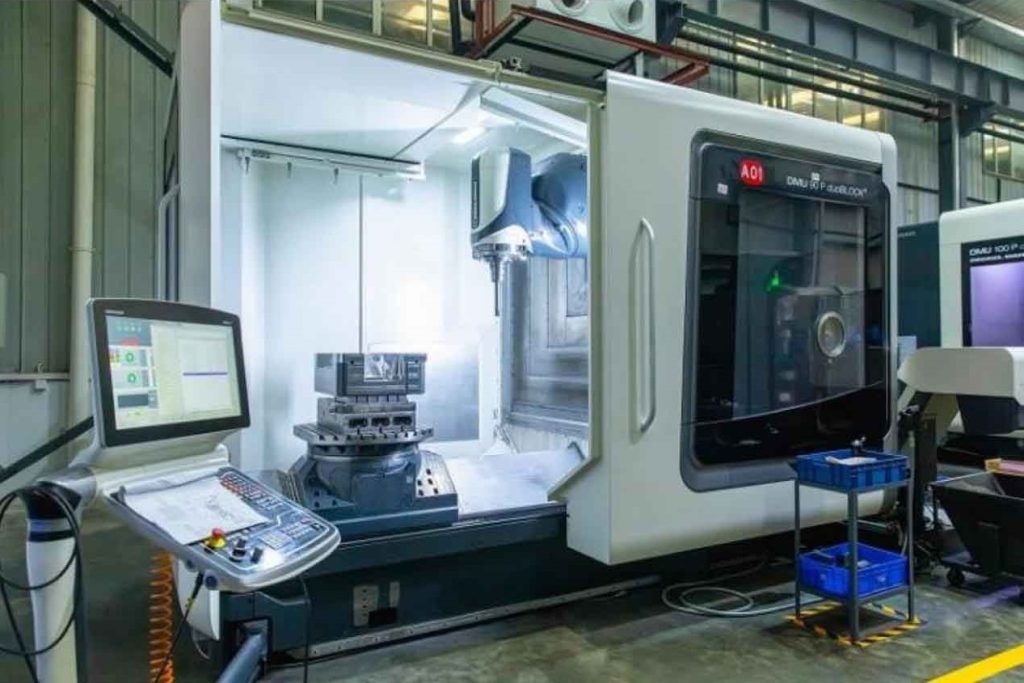

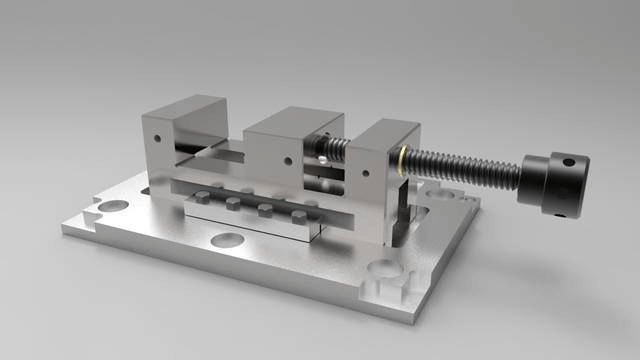

CNC jigs as well as fixtures are the devices which assist in boosting the price of the same parts as well as decreasing the human initiatives required for producing these components, It has actually currently been emphasized earlier that a center turret is a suitable device for creating specific parts of different sizes and shapes, however, for creating comparable posts in multitude its usage will not be economical.

A List Entirely for CNC Fixture

Engineering is about being thorough. And designers carefully scour over the details, reviewing every facet to see to it a CNC fixture design will function effectively. This frequently includes making use of a CNC fixture style list, a device to guarantee layouts catch all information consistently.

Great for brand-new designers, that refer to it throughout the layout process, the testimonial list additionally assists expert developers verify a fast-moving job.

Build and also Launch to Production

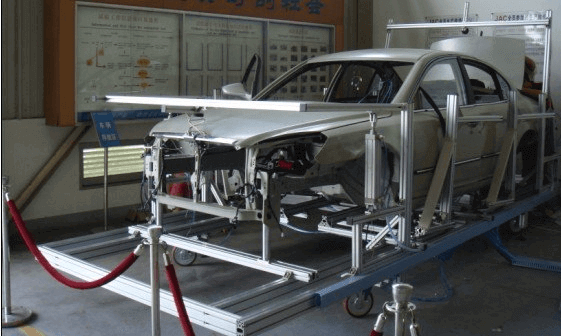

Next off, designers evaluate the CNC fixture layout with the build team to capture any kind of potential manufacturing problems prior to they become issues. With the shared objective of developing the fixture as efficiently as possible, they cover how the parts will certainly be manufactured/assembled and also iron out details concerning machining components, mechanical and hydraulic assembly, and also screening.

Lastly, the CNC component is launched to production. 2 secrets assist reduce production issues: a thorough design process and sharing as much information with the floor as feasible. Educating the manufacturing team upfront helps them recognize the style and its objective.

CNC component layout is enjoyable as well as satisfying!

Designers are problem-solvers that are driven to find options. Creating a CNC component can be a difficulty since some components are tough to hold and refine.

JTR’s engineers have actually designed and constructed thousands of fixtures for different components. Our group prides itself on providing services for complex CNC production problems as well as machining client parts specifically to the plan. Plus, it’s compensating to be part of a group that expands with each other and also shares ideas and know-how. If you are in need of CNC machining service, please do not hesitate to contact us.