Metal alloys like bronze and brass are widely employed in the manufacturing sector nowadays. Due to their distinctive reddish hue, both metals are referred to as “red metals.” These two substances are copper-based alloys with various percentages of other elements, giving rise to a wide range of unique features.

Metal alloys like brass and bronze are widely employed in everyday items. Brass is an alloy of copper and zinc, whereas bronze is primarily an alloy of copper, typically mixed with tin but occasionally with additional metals. These two alloys have a variety of uses because of their characteristics.

It’s crucial to have a firm understanding of what brass and bronze are to be able to compare them.

Although bronze and brass have certain similarities, the following piece concentrates on the unique traits, virtues, and advantages of each material and how they differ from one another.

Let’s first define bronze and brass.

Describe bronze.

Copper and tin predominately make up the metal alloy known as bronze. It is categorized as a copper alloy and is determined by both its functional characteristics and the exact alloying elements used.

As a result, bronze’s features and traits can be enhanced by using various elemental combinations. These metals include silicon, lead, antimony, zinc, nickel, manganese, and many others. Usually reddish-brown or gold in color, bronze is fragile.

Describe brass.

Around 500 BC, users found brass, which had a lot in common with bronze. Brass is an alloy of copper and zinc metals. Metals including tin, iron, aluminum, lead, silicon, and manganese make up its elemental constitution. Brass has a variety of electrical and mechanical capabilities because to its elemental composition. For instance, brass’s zinc component contributes to the material’s improved ductility and strength.

Depending on the zinc to copper ratio, brass can have a variety of colors, including dazzling gold, silver, and many more.

What distinguishes bronze and brass from one another?

- conductivity of electricity

Since copper makes up the majority of both bronze and brass, one may assume that they are both almost as conductive as copper. However, different elemental compositions mean that this is not the case. The electrical conductivity performance of bronze and brass is diminished by the modest amounts of other elements they both contain, including aluminum, tin, zinc, nickel, cobalt, and others.

- Thermal Conductivity

Brass has a far better thermal conductivity than bronze, making it more suitable for the production of radiators, as we observed when the two materials were compared.

- Hardness

Brass is slightly softer than bronze on average. The notion that a harder substance is more brittle applies to bronze, which is significantly more likely to shatter than brass. Bronze might be an excellent option for a project if durability and strength are major concerns. However, brass is by far preferred over bronze if workability is a need.

- Tensile Strength

When choosing a material, many producers in the manufacturing sector pay particular attention to the material’s strength.

In contrast, bronze has a tensile strength of 50 Ksi (350 MPa) when annealed and tensile strength of 92 Ksi (635 Mpa) when cold-rolled tempered. On the other hand, brass has a tensile strength of 53 Ksi (365 MPa) when annealed and 88 Ksi (607 MPa) when cold-rolled tempered

- Uses

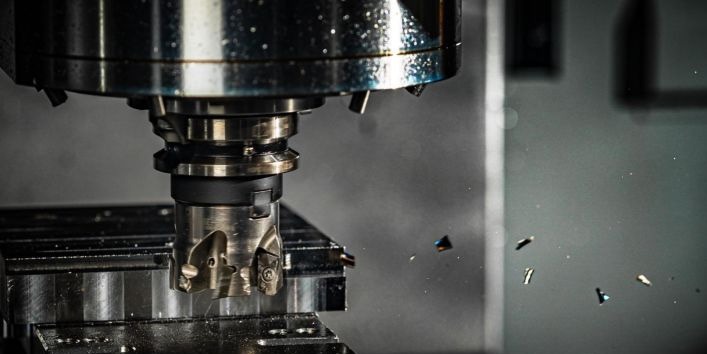

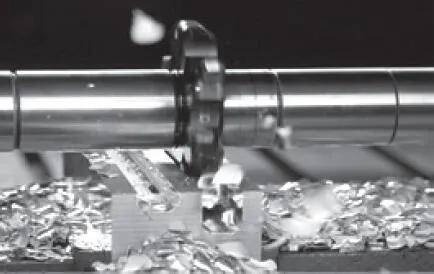

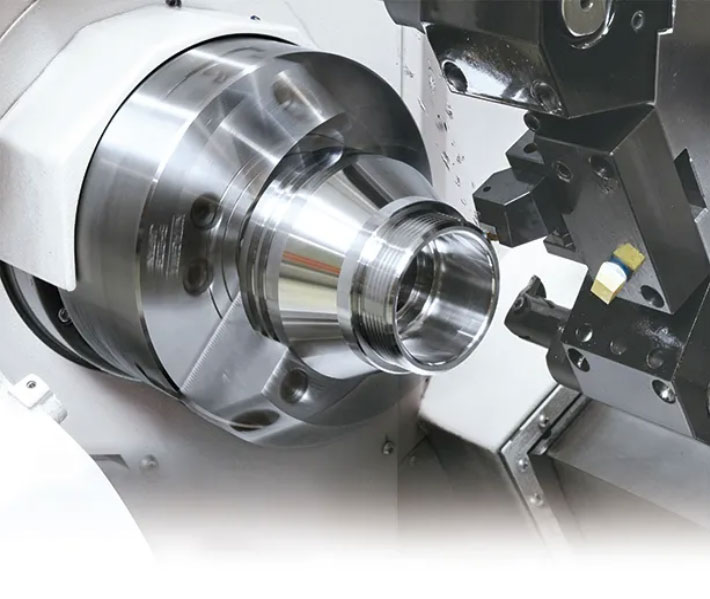

The diverse material compositions of bronze and brass produce varying properties that suit them for various use situations. For instance, brass is a superior option for tubing and pole applications because of its great workability and machinability, whereas bronze has a higher level of resistance to seawater corrosion.

Musical instruments:

Brass is the preferred metal for brass musical instruments including the trombone, tuba, trumpet, cornet, euphonium, tenor horn, and French horn due to its malleability and acoustic qualities. Although the harmonica is a free reed aerophone and the saxophone is a woodwind instrument, both are frequently built of brass.

The most common metal for premium bells is bronze, especially bell metal, which contains roughly 23% tin. A bronze alloy is used to create almost all professional cymbals. The alloy used to make bronze drum kit cymbals is special because it achieves the ideal mix of tone and endurance. Guitar and piano strings both use phosphor bronze.

statues and sculptures:

Because of its dazzling gold-like appearance and relative resistance to tarnishing, brass is frequently used for adornment, statues, and coinage.

Numerous popular bronze alloys have the peculiar but incredibly desired trait of slightly expanding just before they set, filling in the smallest details of a mould that is so frequently employed for cast bronze sculpture.

Designing interiors

Both bronze and brass are employed significantly in many different interior design styles because they both offer beautiful features. Both of them have warm, inviting colors that make them the ideal accent to houses or motels. They do, however, vary, particularly in terms of color. Brass is a lighter color with more tones of yellow and gold. Bronze has a more classic and friendly appearance than brass because of its warmer, redder tones.

Contrarily, brass is frequently utilized as a more conventional and cost-effective replacement for gold. It enhances the elegance and opulence of any space, making it ideal for a luxurious residence or hotel. Due to its popularity as a finish for taps and shower fittings, brass is most frequently found in kitchens and bathrooms.

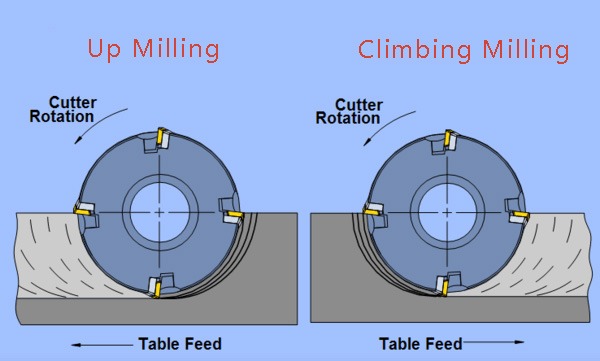

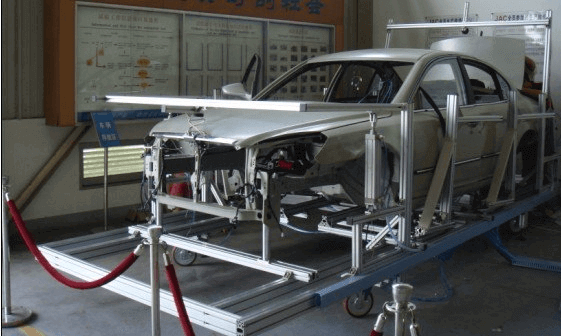

JTR can produce parts according to your requirements and drawings. We provide all kinds of materials, and can select the most suitable materials according to your needs for CNC machining, stamping, die-casting and other manufacturing production.