In contrast to alloy steel, which also contains other elements to change the metal’s properties, carbon steel is simply iron with carbon added to it.

Not that carbon steel is only made of carbon and iron. These extra elements don’t make up a major part of the ingredient list. At the very least, there aren’t enough of a presence to significantly alter carbon steel.

The differences between alloy and carbon steel, as well as their types, uses, alloying components, and physical characteristics, will be covered in this article. This will assist you in selecting the best steel for your project and obtaining premium parts and goods.

What is Alloy Steel?

A form of steel called alloy steel has extra ingredients like manganese, nickel, chromium, or molybdenum. It is possible to enhance a variety of qualities, including toughness, corrosion resistance, and strength. Low alloy steel and high alloy steel are two general categories for alloy steels.

Due to their low price, widespread availability, and superior mechanical qualities, alloy steels are the workhorses of industry. Alloy steels are frequently employed in industries like building and architecture where strength, hardness, and corrosion resistance are crucial. They can also be used to make cookware, home items, and jewelry.

What is Carbon Steel?

A type of steel called carbon steel principally consists of iron with variable quantities of carbon. According to the carbon content, carbon steel can be divided into low carbon steel, medium carbon steel and high carbon steel. Generally also contain a small amount of silicon, manganese, sulfur, phosphorus. Generally, the higher the carbon content in carbon steel, the greater the hardness and the higher the strength, but the lower the plasticity.

What Distinguishes Alloy Steel from Carbon Steel?

Alloy steel is significantly stronger than carbon steel, which is the major distinction between the two metals. This is so that it may be considerably more resilient to wear and tear and much more durable, as it contains additional elements like nickel, chromium, molybdenum, and vanadium. Additionally, alloy steel has higher corrosion resistance and can have its strength increased through heat treatment and quenching. Although carbon steel is far less expensive than alloy steel, it is neither as robust or as resistant to corrosion and wear and tear.

The fact that alloy steel is more difficult to work than carbon steel is another significant distinction between the two types of steel. This is due to the fact that alloy steel is significantly harder than carbon steel, making it more difficult to bend and shape. Additionally, alloy steel needs to be treated at greater temperatures and with more heat than carbon steel does.

- Applications

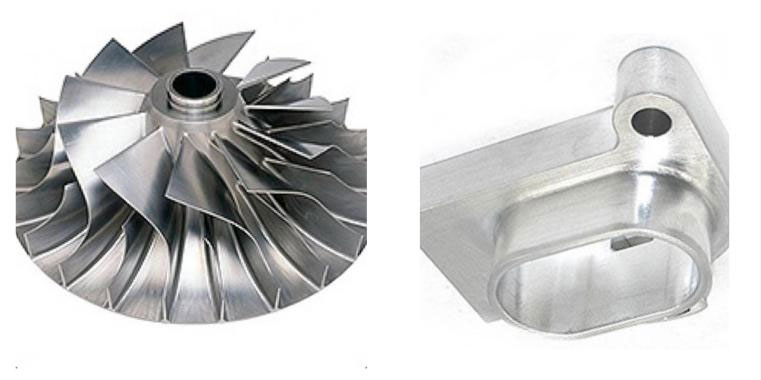

The production of girders, structural sections, aviation parts, ship propellers, bars, rails, rods, screws, bolts, nails, and wires all employ alloy steel.

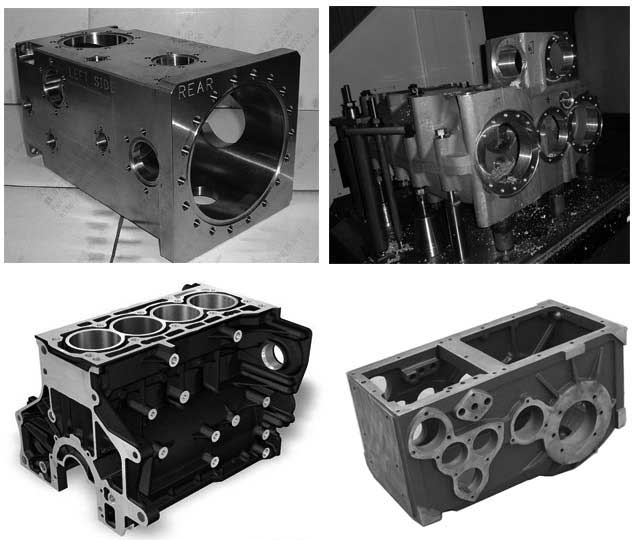

On the other hand, carbon steel is also widely used in various manufacturing sectors for the creation of parts for machines, cans, springs, dies, wheels, crankshafts, machinery, pipes, and building and bridge work.

- Composition

In addition to iron and carbon, alloy steel also contains a significant amount of other alloying components.

In contrast, carbon alloy has a low amount of other elements and a high percentage of carbon.

- Hardness

The higher the carbon content in carbon steel, the higher the hardness.

- Strength & Toughness

Alloy steel has higher strength and toughness than carbon steel

What Kind Should You Employ?

The use for which they will be put determines whether to employ alloy or carbon steel. Due to their improved qualities compared to normal carbon steels, alloy steels would be the best option for you if you need high-strength materials that are also resistant to wear or corrosion. However, if money is a concern, you might want to use carbon steels instead because, depending on their makeup, they can be less expensive than alloy steels.

Conclusion:

Finally, it should be noted that there are distinct variations between alloy steel and carbon steel that should be taken into account when determining which will be most useful for your project or application. Although they are more expensive than standard carbon steels, alloy steels have higher strength and resistance to wear or corrosion. On the other hand, normal carbon steels may be a better option if cost is a concern because of their reduced price based on their composition.

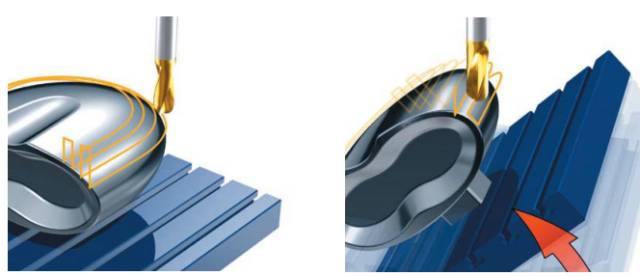

JTR employs qualified engineers who can assist you in choosing the right materials for CNC machining or other production processes including stamping, die casting, and others. JTR can implement the manufacturing process for you using the drawings you supply.