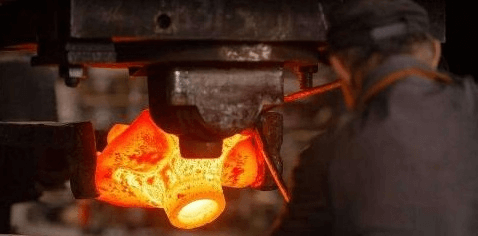

Forging, an ancient metalworking technique, continues to be a cornerstone of modern manufacturing. The process involves shaping and forming metals through the application of compressive forces, resulting in strong and reliable components. The choice of material is a crucial aspect of forging, as it directly influences the performance, durability, and suitability of the final product. In this article, we will explore the diverse range of materials that can be used in forging and provide insights into the considerations for selecting the most appropriate material for your forging needs.

What Materials Can Be Used in Forging?

Forging can be performed on a wide range of materials, including:

Ferrous Metals:

- Carbon Steel: Commonly used for forging due to its strength, durability, and cost-effectiveness. Forged carbon steel offers a broad range of grades with varying carbon content, enabling the production of components tailored to specific requirements.

- Alloy Steel: Contains additional elements such as chromium, nickel, or molybdenum, forged alloy enhances properties like strength, corrosion resistance, and heat resistance.

- Stainless Steel: Prized for its corrosion resistance, stainless steel is often chosen for forged components exposed to moisture, chemicals, or extreme temperatures. Forged stainless steel is versatility, durability, and aesthetic appeal, which make it a popular choice in various industries.

- Tool Steel: Designed for specific tooling applications, offering high hardness, wear resistance, and toughness.

Non-Ferrous Metals:

- Aluminum: Aluminum, known for its lightweight nature and excellent corrosion resistance, finds extensive use in forging applications where weight reduction and a high strength-to-weight ratio are desired. Forged aluminum components are prevalent in aerospace, automotive, and sporting goods industries.

- Copper: Copper and its alloys possess excellent electrical and thermal conductivity, making them suitable for electrical and heat transfer applications. Forged copper components are commonly found in electrical connectors, plumbing fittings, and heat exchangers.

- Brass: A combination of copper and zinc, offering good corrosion resistance and machinability, often used in fittings, valves, and decorative applications.

- Titanium: Known for its high strength-to-weight ratio, corrosion resistance, and biocompatibility, commonly used in aerospace, medical, and chemical industries.

- Nickel-based Alloys: Exhibit high-temperature resistance, strength, and corrosion resistance, commonly used in turbines, chemical processing, and aerospace applications.

Exotic Materials:

- Superalloys: High-performance alloys with exceptional strength, heat resistance, and corrosion resistance, used in extreme conditions such as jet engines and gas turbines.

- Refractory Metals: Tungsten, molybdenum, and tantalum, known for their high melting points and resistance to heat and wear, used in aerospace, defense, and electronics.

- Precious Metals: Gold, silver, and platinum, often used for decorative or high-value applications.

It’s important to note that the choice of material for forging depends on the specific application requirements, such as mechanical properties, corrosion resistance, temperature resistance, and cost considerations. Different materials may require specific forging processes and techniques to achieve the desired final product.

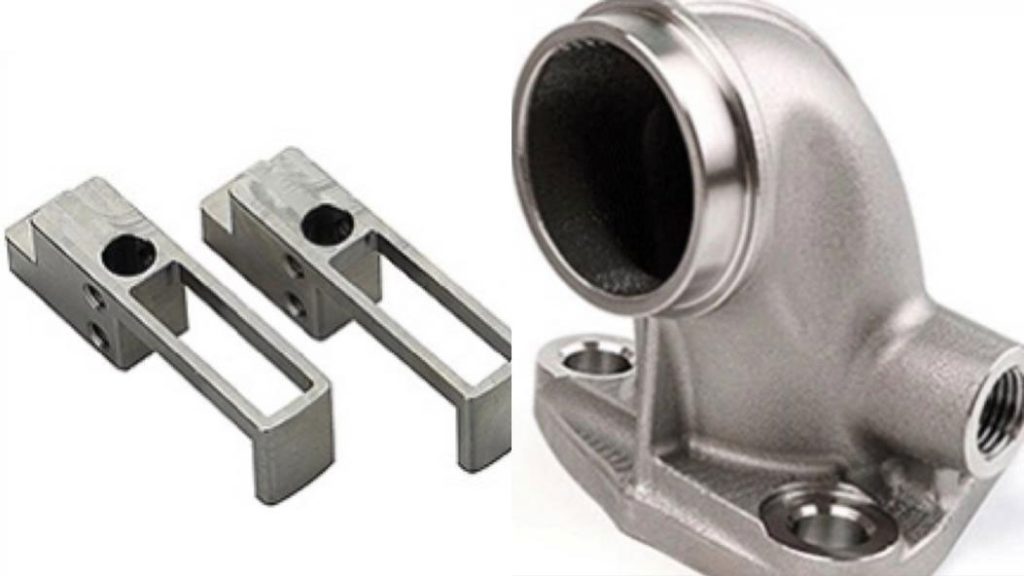

Considerations for Material Selection in Forging

When it comes to material selection in forging, several considerations should be taken into account to ensure the desired performance and characteristics of the final forged component. Here are some key considerations:

- Mechanical Properties: Evaluate the mechanical requirements of the component, such as strength, hardness, toughness, and fatigue resistance. Select a material that possesses the necessary mechanical properties to withstand the anticipated loads, stresses, and operating conditions.

- Heat Resistance: Consider the temperature range the forged component will be exposed to during its service life. Choose a material that can maintain its mechanical properties and structural integrity under those temperature conditions. Heat-resistant alloys or high-temperature steels may be required for applications involving elevated temperatures.

- Corrosion Resistance: Assess the likelihood of exposure to corrosive environments, including moisture, chemicals, or atmospheric conditions. Select a material that offers adequate corrosion resistance to prevent degradation or premature failure of the forged component. Stainless steels, nickel-based alloys, or corrosion-resistant alloys may be suitable options.

- Wear and Abrasion Resistance: If the forged component will be subjected to abrasive wear or sliding contact, consider materials with high wear resistance. Hardened or alloyed steels, tool steels, or wear-resistant alloys may be appropriate for such applications.

- Machinability: If subsequent machining operations are required after forging, consider the machinability of the material. Some materials may be more challenging to machine, leading to increased costs or difficulties in achieving the desired dimensions or surface finish. Consult with machining experts to determine the most suitable material for ease of machining.

- Weldability: If the forged component will be joined to other parts or require welding during fabrication, evaluate the weldability of the material. Certain materials may require specific pre-welding treatments, post-welding heat treatment, or filler material considerations. Compatibility between the forged material and potential welding techniques is essential.

- Cost Considerations: Assess the cost-effectiveness of the material. Evaluate factors such as the availability, market price, and overall cost of the material. Consider the trade-off between material cost and the performance requirements of the component.

- Industry Standards and Specifications: Check if there are specific industry standards, specifications, or regulations that dictate the material requirements for the intended application. Compliance with these standards may be essential for quality assurance, safety, and regulatory compliance.

- Supplier Availability and Expertise: JTR is a CNC machining China service supplier, and also a professional forging service provider working with a particular material. We have experience and knowledge in handling the chosen material and can deliver high-quality forged components.

By carefully considering these material selection factors, you can choose a material that aligns with the requirements of your forging application, ensuring optimal performance, longevity, and cost-effectiveness of the final forged component.