Whenever a new project of yours is about to launch in the industry, the first thing you need to consider is probably how to produce the parts. Selecting the right manufacturing method to process your precious products isn’t easy, and most of us will face the choice between die casting and CNC machining. As the two most commonly used material processing methods in modern industry, die casting and CNC machining both have their own unique advantages and irreplaceable features. The question is not which one is better ‘cause both are pretty good in some ways. What you got to figure out is just which one is suitable for you.

What is CNC Machining And Die Casting?

Yep, you need to know what they are before making a decision. Generally, both of them are manufacturing processes capable of producing the best parts. Die Casting is a relatively ancient technology that humans have been using for nearly two centuries, while machining through computer numerical control wasn’t possible till the 1940s. But coming onto the stage later doesn’t always mean it’s better. Let’s take a thorough look at them.

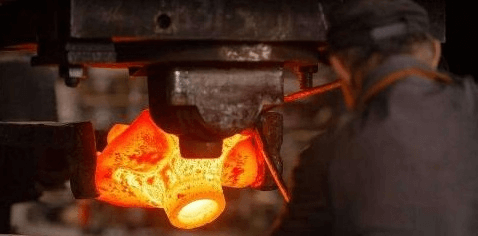

Die Casting

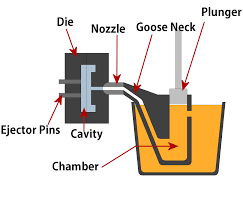

Die casting is one of the casting processes. It produces parts by melting the metal first and then leading it into a pre-designed mold (the die) under high pressure. After the mold is cooled down and the metal is hardened, a preliminary product is completed.

Die casting creates parts with great dimensional precision and a smooth surface, but in most cases, the parts would need a little bit more machining.

CNC Machining

CNC machining is the logogram for Computer Numerical Control machining – the machining process is under the control of a computer program. Like traditional hand-machining, CNC machining takes part from a bulk of material. The process is famous for its production speed, accuracy and material versatility. The computer program converts a CAD design into directions for machining tools, thus no mold or prototype is needed.

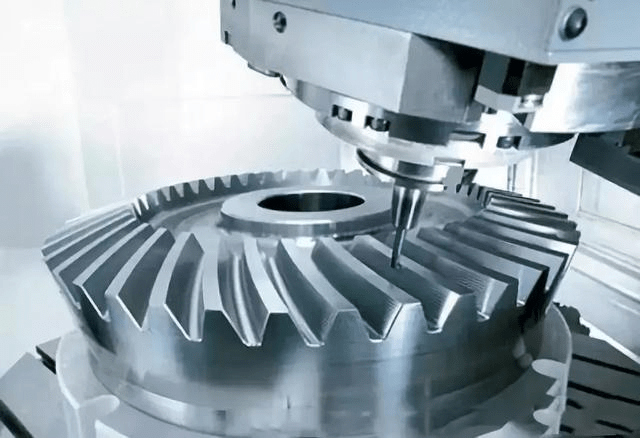

CNC Machining vs. Die Casting – Choose Your Best Process

In fact, the two processes are quite different in principle, but both can produce high-quality parts. To let you have a clear comparison, below I’ve created a table showing their capabilities in different aspects.

| FeatureProcess | Die Casting | CNC Machining |

| Material Versatility | Mostly metal(high-fluidity) – Alloy of Aluminum, Zinc, Copper, Magnesium, etc. | Metal and plastic |

| Production Speed | Fast | Fast |

| Cost-efficiency | Cost-efficient for large volume production | Cost-efficient for low volume production |

| Accuracy | High | Very high |

| Ability to Process complex Parts | Medium | Medium |

| Material Waste | Material barely wasted | Material waste is a must |

Except for factors like material selection, the two processes are comparable in almost all aspects, which means if what I need are metal parts, the biggest influence on my choice will be the cost. Many people in the industry would take die casting for large volume production and use CNC machining for prototyping or low volume production because of the costs. This is the factor you should take into consideration too.

Why is Die Casting Expensive for Low-volume Production then?

Mainly because of the tooling costs. In order to make the molten metal shape, a hardened steel tool is necessary for this ancient tech. It’s an inevitable big expensive at the beginning of your manufacturing. But fortunately, the subsequent cost is relatively low because there are very few casting steps. High in capital costs while low in marginal costs, this feature of die casting makes it a good solution for large volume and long-term production.

In contrast, a CNC machine is equipped with all the tools it needs (depending on the type of machine, it can be a cutter, a drill, a laser gun, etc.) But normally the marginal cost for CNC machining is higher than die casting.

To be noticed, in actual industrial production, those two processes are often combined together. Die casting is used to cast the main body of the part to avoid material waste, then the details are left to CNC machining for higher precision. So the best way for you to know the exact manufacturing cost is to get a quote.

Choose your right process

JTR Machine has been engaged in both metal casting and CNC machine services for many years. We can provide you with whichever manufacturing method you want and quality is guaranteed.

JTR also provides multiple post-processing options like surface finishes. If metal casting and CNC machining won’t meet your product demand, we can offer other manufacturing processes like 3D printing. Feel free to contact us and get a free quote.