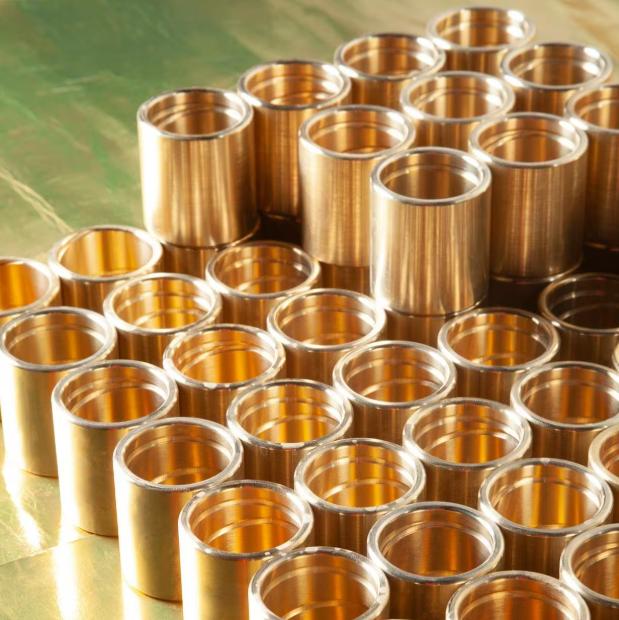

Due to its good machinability, corrosion resistance, and its potential to be decorative, brass is frequently used in household components. However, raw brass tends to tarnish and oxidize if exposed to air and moisture over time. As custom brass parts manufacturers, we know that surface treatments on brass help protect parts from corrosion while enhancing their aesthetic and functional performance. Whether as a consumer searching for a decorative finish on a new fixture or a designer specifying custom brass parts for a project, knowing the options lets one make a well-informed choice.

Common Brass Surface Treatment Methods

The world of brass surface finish offers a diverse range of options, each with unique characteristics and aesthetic outcomes. These methods can be broadly categorized into mechanical, chemical, electrochemical, thermal, and special decorative processes.

Mechanical Treatment Processes

Mechanical treatments alter the brass surface through physical abrasion or shaping, influencing its texture and reflectivity.

- Polishing Brass: This process involves abrasive compounds and buffing wheels to create a smooth, highly reflective, mirror-like finish. It’s the go-to for a classic, luxurious look. For example, a polished brass shower system or polished brass toilet handle exudes a sense of traditional elegance. The goal is to achieve maximum luster by removing any surface imperfections.

- Brushed Brass: Achieved by abrading the surface with a fine-grit abrasive belt, brushed brass features a subtle, directional satin sheen with fine parallel lines. This finish is less reflective than polished brass and helps to mask fingerprints and minor scratches. Think of a brushed brass shower head or brushed brass toilet lever providing a modern, understated aesthetic.

- Sandblasting Brass: Involves propelling fine abrasive particles at high velocity onto the brass surface. This creates a matte, non-reflective texture that can range from fine to coarse depending on the abrasive used. While less common for purely decorative purposes in residential settings, sandblasting brass can be used to create unique tactile finishes or prepare surfaces for further coating by improving adhesion.

These mechanical methods are fundamental in establishing the initial look and feel of the brass component before any protective layers are applied.

Chemical Treatment Processes

Chemical treatments involve using chemical solutions to alter the surface of the brass, either by cleaning it or by inducing a reaction that changes its color or protective properties.

- Pickling Brass: This is a preparatory chemical process that uses acid solutions to remove oxidation, scale, and surface contaminants from brass. It’s often performed before other finishing processes like electroplating or lacquering to ensure a clean, reactive surface. While it doesn’t offer a decorative finish on its own, it’s crucial for achieving optimal results in subsequent treatments. For instance, pickling brass ensures that a subsequent antique finish adheres uniformly.

- Chemical Coloring / Patination: This involves chemical reactions on the brass surface to create controlled oxidation layers, resulting in various colors like bronze, brown, black, or the classic green/blue patina. This method is often used to achieve antique finish brass effects. The exact shade can vary depending on the chemical composition and process duration. For example, creating an antique brass bridge faucet often involves carefully controlled chemical baths to achieve its distinctive aged appearance.

These chemical processes offer a way to achieve specific colors and aged looks that mechanical treatments cannot, often providing a more durable and integrated color layer.

Electrochemical Treatment Processes

These processes use electricity to deposit a layer of another material onto the brass surface, significantly enhancing its properties.

- Electroplating Brass: This is a highly effective method where a thin layer of another metal (such as nickel, chrome, silver, or gold) is deposited onto the brass surface using an electric current. Electroplating brass offers superior wear resistance, hardness, corrosion protection, and a wide range of aesthetic finishes. For example, a polished brass shower valve can be electroplated with chrome to offer a silver-like shine with enhanced durability, or with gold for a luxurious finish. This process is commonly used for high-use items where longevity and resistance to tarnishing are paramount. Data shows electroplated finishes can significantly extend the lifespan of brass fixtures in high-moisture environments.

Electroplating transforms the surface properties of brass, offering a protective shield that is both functional and decorative.

Thermal Treatment Processes

Thermal treatments involve heating and cooling the brass to alter its internal structure, primarily affecting its mechanical properties rather than its surface appearance as a final finish.

- Annealing Brass: This process involves heating brass to a specific temperature and then slowly cooling it. Annealing brass is primarily used to increase the ductility and reduce the hardness of the material, making it easier to machine, form, or deep-draw without cracking. While not a surface finish in itself, it’s a critical pre-treatment step in manufacturing complex custom brass parts before any final surface treatments are applied. For example, complex custom brass parts that require extensive bending might undergo annealing to prevent fracturing during fabrication.

Annealing is crucial for the workability of brass, ensuring that intricate designs can be achieved before aesthetic finishes are applied.

Special Decorative Processes

These methods often combine aspects of the above to achieve unique visual effects or protective qualities.

- Lacquering/Clear Coating: After mechanical or chemical treatments (like polishing or antiquing), a clear lacquer or polymer coating is often applied to seal the brass surface and prevent oxidation and tarnishing. This is vital for maintaining the desired aesthetic, especially for polished brass or brushed brass components. Without a lacquer, a polished brass shower system would quickly dull and tarnish.

- Unlacquered Brass: In contrast to lacquering, unlacquered brass components are left without any protective coating, allowing the brass to naturally age and develop a unique patina over time. This is a deliberate choice for those who appreciate the evolving character of brass. An unlacquered brass toilet lever or unlacquered brass single hole faucet will gradually darken and develop unique color variations, telling a story of its use and environment. This “living finish” is highly sought after for its authenticity and vintage appeal.

These special processes offer a way to either preserve the initial finish or allow the brass to develop a dynamic, evolving character.

How to Choose the Right Brass Finish for Your Home Components?

Selecting the ideal brass finish for your home components involves balancing aesthetic preferences with functional requirements and maintenance considerations. As a leading custom brass parts manufacturer, we guide both custom brass parts clients and consumers through this decision-making process.

Key Considerations Before Choosing

When choosing a brass surface finish, think about these factors:

- Aesthetic Style: Does your home lean towards modern, traditional, industrial, or rustic? The finish should complement your existing decor. A polished brass finish, for instance, suits classic and luxurious settings, while brushed brass aligns with contemporary and minimalist designs.

- Durability and Wear: How much wear and tear will the component experience? High-touch items like door handles or faucets in busy areas might benefit from more durable finishes like electroplating or those with protective lacquers. Antique finish brass is often very forgiving of minor scratches due to its inherent varied texture.

- Maintenance: Are you willing to regularly clean and polish your brass fixtures? Polished brass requires more frequent cleaning to maintain its shine, whereas brushed brass and antique brass are more forgiving of fingerprints and water spots. Unlacquered brass requires the least “cleaning” in terms of maintaining its initial look, as its charm lies in its natural aging.

- Environment: Will the component be exposed to moisture, chemicals, or extreme temperatures? For example, brushed brass shower head and other bathroom fixtures need finishes that can withstand constant humidity and water. Electroplated finishes offer excellent corrosion resistance in such environments.

By considering these aspects, you can narrow down the options and find a finish that not only looks great but also performs well in its intended setting.

Application Analysis by Scenario: Matching Brass Components with Finishes

Your home offers various challenges and aesthetic opportunities for brass components. Let’s explore some common applications.

Bathroom Applications

Bathrooms are high-moisture environments, making durability and resistance to tarnishing key.

| Common Components | Recommended Finish |

| Brushed brass shower head / system | Brushed finish: modern, anti-fingerprint |

| Polished brass shower system / valve | Polished finish: luxurious, reflective |

| Vintage brass shower fixtures / drain | Antique finish brass for traditional aesthetics |

Kitchen Applications

Kitchens are high-traffic areas exposed to food, grease, and cleaning agents. Durability and ease of cleaning are paramount.

| Common Components | Recommended Finish |

| Brushed brass toilet lever / screen / drain cover | Brushed or satin for fingerprint resistance |

| Polished brass toilet handle / supply line | Bright, clean look that matches polished fixtures |

| Unlacquered brass toilet handle / tank lever | Aged patina lovers’ choice; low-maintenance with time |

Toilet & Sanitary Hardware

Toilet components often experience frequent handling, so finishes that can withstand touch and maintain their appearance are important.

| Common Components | Recommended Finish |

| Brushed brass toilet lever / screen / drain cover | Brushed or satin for fingerprint resistance |

| Polished brass toilet handle / supply line | Bright, clean look that matches polished fixtures |

| Unlacquered brass toilet handle / tank lever | Aged patina lovers’ choice; low-maintenance with time |

Tips for Custom Brass Parts Buyers

For product developers and bulk buyers working with custom brass parts manufacturers, consider the following:

- Material uniformity: Ensure the brass grade is suitable for chosen treatment.

- Volume and consistency: Some treatments like electroplating are more cost-effective at scale.

- Finishing tolerance: Polishing and brushing can slightly affect dimensions—plan accordingly.

- After-treatment protection: For finishes like antique finish brass, protective topcoats may be added for stability.

Here are the comparisons among common brass surface finish:

| Finish Type | Aesthetic Appeal | Durability/Maintenance | Ideal Application Scenarios |

| Polished Brass | High-gloss, reflective, luxurious | Low (shows fingerprints, tarnishes easily without lacquer) | Traditional, high-end, statement pieces (e.g., polished brass shower system) |

| Brushed Brass/Satin Brass | Matte, soft sheen, modern | Medium (resists fingerprints better, easier to maintain) | Contemporary, minimalist, high-touch areas (e.g., brushed brass shower head) |

| Antique Finish Brass | Aged, rustic, varied tones | High (hides wear well, low maintenance) | Vintage, farmhouse, eclectic (e.g., antique brass bridge faucet) |

| Unlacquered Brass | Natural, evolving patina | Varies (develops natural patina, low maintenance) | Authentic, living finish, natural aesthetic (e.g., unlacquered brass toilet lever) |

| Electroplated Brass | Wide range (e.g., chrome, nickel, gold) | Very High (superior corrosion and wear resistance) | High-moisture, high-use, demanding environments (e.g., brushed brass shower valve) |

Choosing Professional Custom Brass Parts Manufacturers

The finish of brass parts greatly affects the appearance and the lifetime of the home components. Moreover, the surfaces of brass offer various options such as polished brass surfaces which are classic and elegant, brushed brass which offers a modern charm, and antique finish which is timeless and captivating while unlacquered brass is a beauty which is still evolving. Having knowledge on the options of surface treatment of brass allows individuals to choose a treatment that matches your home style and needs both functionally and aesthetically.

As extensive custom brass parts manufacturers, we offer a variety of surface finishes and proper guidance for our customers. Seeking help from an experienced manufacturer guarantees proper execution of custom designs like the shower and the brushed brass corner valves to ensure that the whole shower system is properly fitted. Feel free to contact our experts to tailor your designs and to know the methods that we use to achieve the brass finish desired.