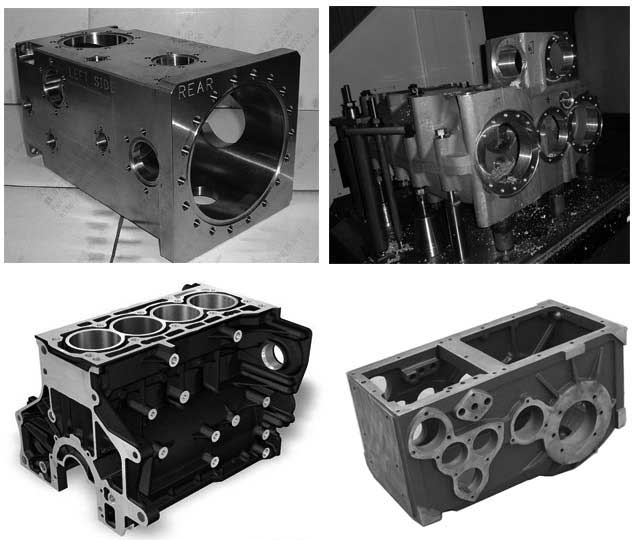

With the development of science and technology and the improvement of manufacturing levels, curved parts and curved molds are more and more widely used in the industrial field. When machining curved parts, milling is usually used for processing. So what should be paid attention to when milling surfaces? We think we should pay attention to the following points:

Factors Should be Paid Attention At When Assembling Milling Machine Fixtures

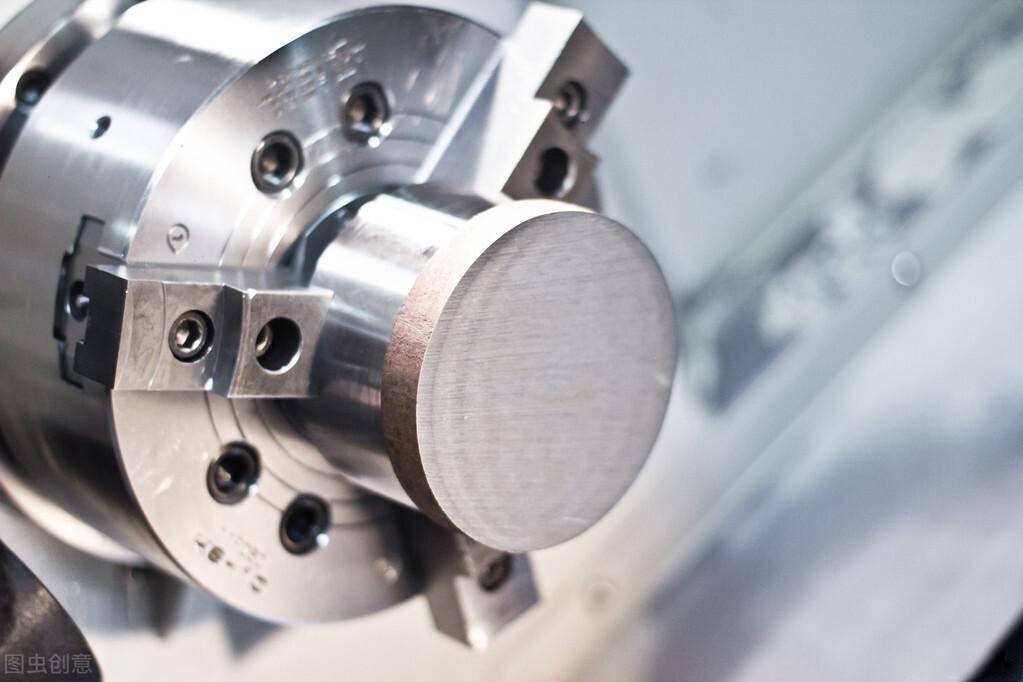

1. In order to improve the stability of the milling machine fixture installed on the machine tool and the seismic performance under dynamic conditions, the structure of various devices should be compact, the center of gravity of the fixture should be as low as possible, and the contact area between the clamping body and the machine tool table should be large.

2. Use milling machine to improve production efficiency (short cutting time). When designing fixtures, we should consider how to quickly install workpieces to shorten auxiliary time. Generally, the fixtures are set with components that determine the position and direction, so as to quickly adjust the fixtures and machine tools. relative position.

3. When assembling the milling machine fixture, the outflow of chips and the convenience of cleaning should also be considered. A large number of chips are generated during milling, and there should be enough chip removal space. Large-scale fixtures should consider chip removal ports and chip grooves; protective covers should be added to the parts and spaces that are not easy to remove chips. Cutting fluid is used during processing, and the flow direction and recovery of cutting fluid should be considered in the design of the clamp. For heavy-duty milling machine fixtures, lifting rings, etc. should also be set on the clamping body for ease of handling.

Matters Needing Attention When Milling Surfaces

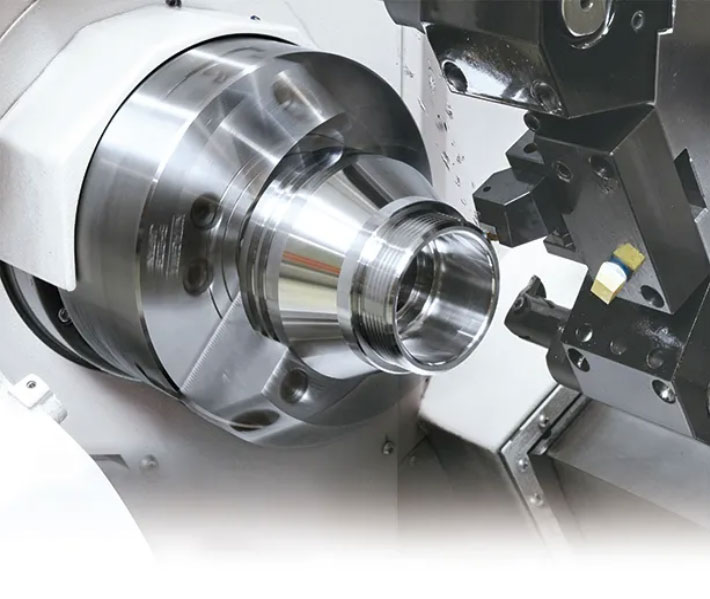

In CNC milling, milling the surface is relatively complicated, because there are many problems that need to be paid attention to during the machining process.

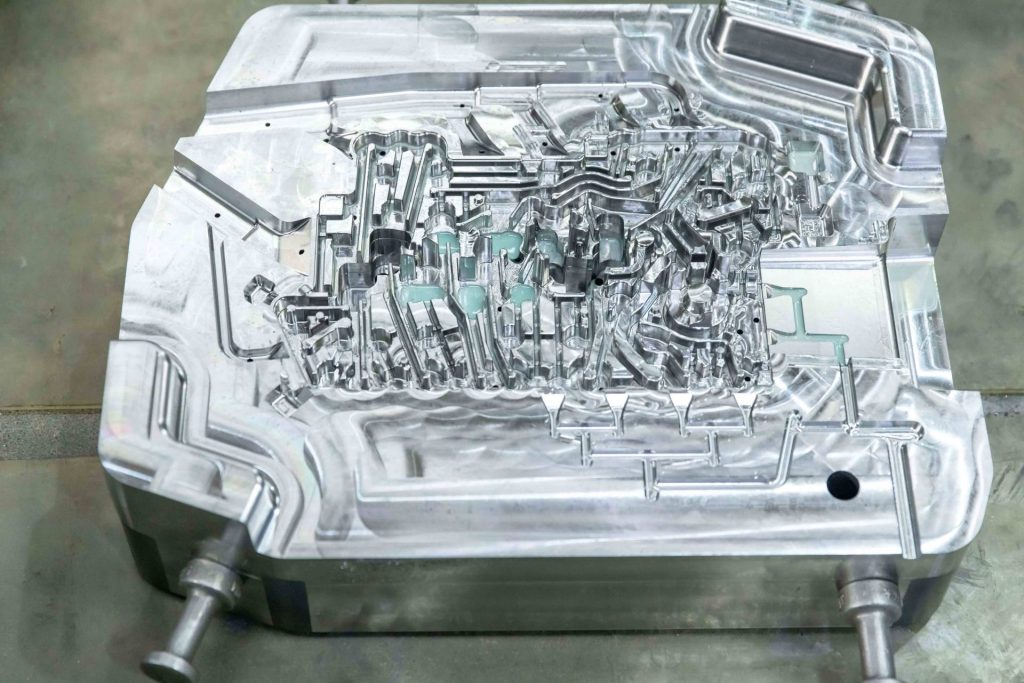

1. Rough milling

When rough milling, according to the allowance given by the surface to be processed, the end mill should be used to mill the contour surface layer by layer. This rough milling method is highly efficient. The rough-milled surfaces resemble terraces on a hillside. Each depth of cut depends on the roughing accuracy and workpiece material.

2. Semi-finishing milling

In the process of machining parts with more complex surfaces or large parts, add a step of semi-finishing. The purpose of semi-finishing milling is to remove the steps of the “terraced field”, so that the machined surface is closer to the theoretical surface. The ball end milling cutter generally leaves a machining allowance of about 0.5mm for the finishing process. Semi-finishing has a larger row and step than finishing.

3. Finishing

Finally, the theoretical surface is processed. When finishing a curved surface with a ball end milling cutter, the row cutting method is generally used to form a certain angle with the semi-finishing tool path.

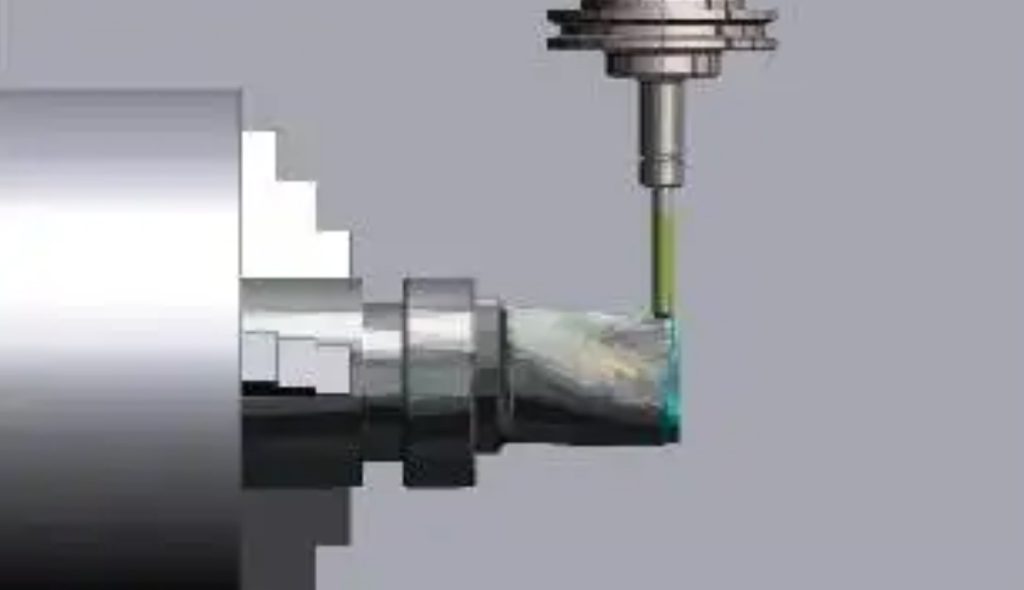

4. Reasonable use of ball-end milling cutter

When the ball-end milling cutter is milling a curved surface, the cutting speed at the tip is very low. If the ball cutter is used to mill a relatively flat curved surface perpendicular to the machined surface, the surface quality of the ball cutter tip is relatively poor, so it should be properly The spindle speed should be increased significantly, and cutting with the tool tip should be avoided.

5. Avoid vertical cutting

The best way is to use a spiral lower knife, and then use the side edge to cut laterally after entering a certain depth. The CAM software generally automatically sets the oblique inserting or helical cutting to protect the tool. When milling the groove face, process holes can be pre-drilled for cutting.

6. Detection

When milling curved parts, it is necessary to detect the workpiece in time and arrange finishing according to the tolerance size.

7. Check

When milling the complex surface of the mold cavity, it generally requires a long cycle. Therefore, the machine tool, fixture, and tool should be properly checked before each start-up milling to avoid failure in the middle.

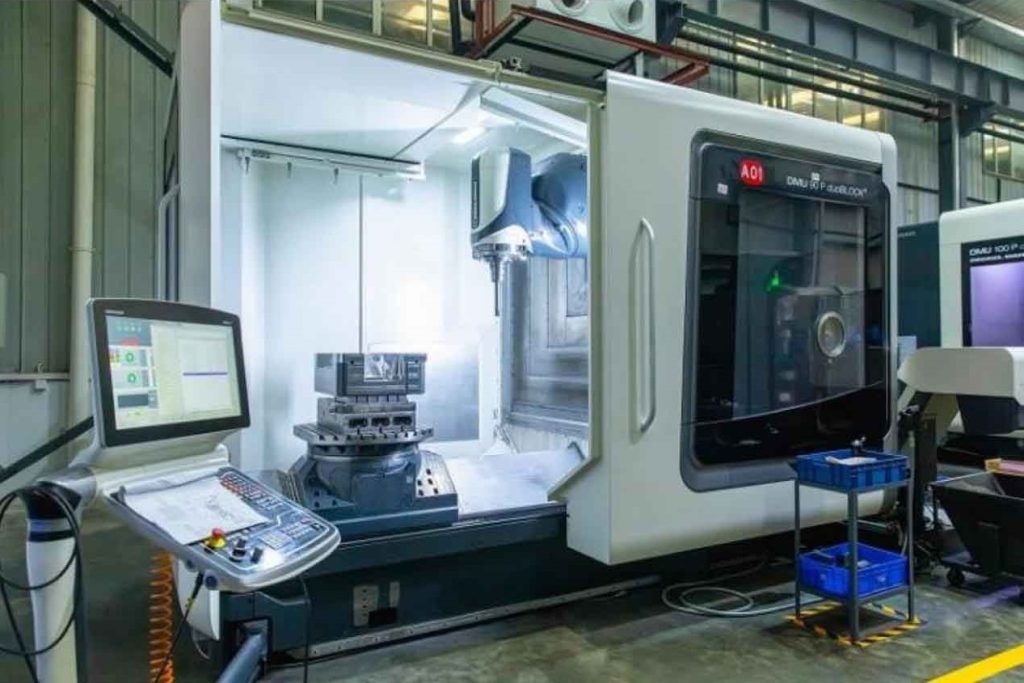

At JTR, we have a special team to analyze our customers’ products design, give them professional advice, and help decrease machining errors. Consult us if you have any requirements.