First, understand the definitions of the two:

What is Powder Coating?

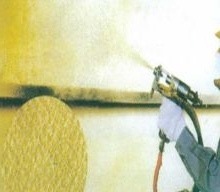

Powder spraying is the use of powder spraying equipment (electrostatic spraying machine) to spray powder coating on the surface of the workpiece. Due to the effect of static electricity, the powder will be uniformly adsorbed on the surface of the workpiece to form a powder coating. The powder coating is then baked and leveled at high temperatures to form a final coating with various effects.

How Does Powder Coating Work?

The working principle of powder spraying is to use the principle of electrostatic spraying:

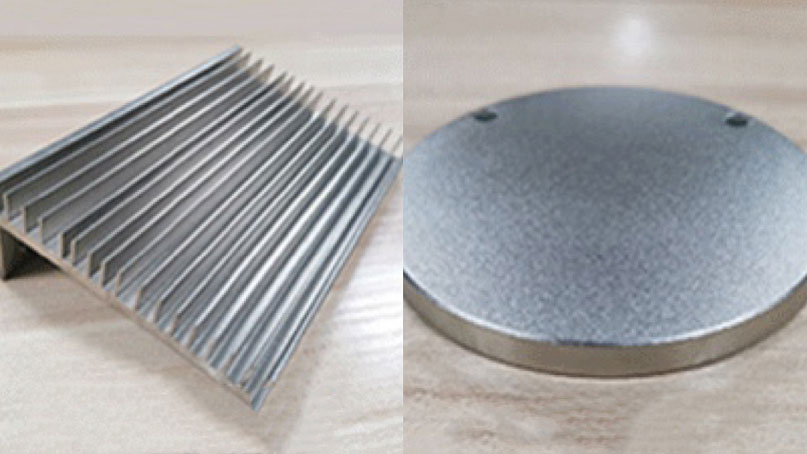

Take aluminum profiles as an example:

The dry powder is adsorbed on the metal aluminum profile, and the powder is cured into a solid and bright coating with a thickness of about 60 microns after being grilled at a high temperature above 200 °C.

After powder spraying, the surface of the product can be smooth and smooth, with uniform color, strong acid resistance, alkali resistance, impact resistance, wear resistance, and can withstand strong ultraviolet radiation and acid rain for a long time without coating powdering, Fading, falling off, etc.

Under typical circumstances, the service life of powder-coated aluminum profiles is 30 years. Its surface coating is guaranteed not to fade, not change color, not to crack within 5-10 years. Its weather resistance and corrosion resistance are better than ordinary aluminum, and its colors are diverse.

What Are the Characteristics of Powder Coating?

1. This product does not contain solvents or volatile toxic substances. Therefore, there are no public hazards such as poisoning, fire, and waste discharge.

2. The utilization rate of raw materials is high, and some powders can be recycled. The highest utilization rate can even reach more than 99%.

3. After pre-treatment of the object to be coated, one-time construction, without primer coating, can obtain a coating film with sufficient thickness. Easy to realize automatic operation, high production efficiency, can reduce costs.

4. The coating is dense, has good adhesion, good impact strength and toughness, and has high corner coverage. Has excellent chemical resistance and electrical insulation properties.

5. The powder coating is safe and convenient to store and transport.

What is Spray Paint?

Spray paint is dispersed into fine and uniform droplets by means of pressure or centrifugal force through a spray gun or disc atomizer and then applied to the surface of the object to be coated.

What is the Principle of Spray Paint?

Spray painting is to use of a spray gun to atomize the paint with the help of pressure or centrifugal force and then disperse it into uniform and fine droplets, which are coated on the surface of the object.

What Are the Characteristics of Spray Paint?

1. The production efficiency of spray painting is high, and it is suitable for manual operation and industrial automation production. It has a wide range of applications, mainly in the fields of hardware, plastics, the military industry, ships, etc. It is the most commonly used coating method today.

2. The environment of the painting operation requires a dust-free workshop. The spraying equipment includes a spray gun, spray booth, paint supply room, spraying workpiece conveying equipment, curing furnace/drying furnace, fog elimination, wastewater, waste gas treatment equipment, etc.

3. The main problem in spraying is the highly dispersed paint mist and volatilized solvent, which not only pollutes the environment, is not conducive to human health, but also wastes paint and causes economic losses.

What is the Difference Between Powder Coating and Spray Paint?

The advantages of powder coating over traditional paint processes are:

1. High efficiency: due to one-time film formation, productivity can be increased by 30-40%.

2. Energy saving: reduce energy consumption by about 30%.

3. Less pollution: no organic solvent volatilization (excluding toluene, xylene, and other harmful gases in paint coatings).

4. High utilization rate of coatings: up to 95% or more, and the powder can be reused after recycling.

5. Good film performance: the one-time film thickness can reach 50-80μm, and its comprehensive indicators such as adhesion and corrosion resistance are better than those of the painting process.

6. High yield: the second respray can be carried out before curing.

7. The spraying effect of powder spraying is superior to the spraying process in terms of mechanical strength, adhesion, corrosion resistance, and aging resistance.

JTR can configure the most suitable workpiece surface treatment method according to the specific needs of customers. We have rich experience in CNC machining, stamping and injection molding, etc., and can provide you with cost-effective services.