Sheet metal parts are widely used, and are a kind of parts processed and manufactured with sheet metal as a material, which are used in various fields and play an important role. In people’s production and life, sheet metal parts can be seen everywhere, and they are indispensable parts in various industries.

Small sheet metal parts are a special kind of sheet metal parts, which are mostly manifested in that the distance between holes and apertures are small, and the distribution of holes is relatively dense. Using the conventional one-time punching and forming processing method, the phenomenon of punch instability is prone to occur, and the loss of the mold is also large, which affects the service life of the mold. How to manufacture a precise small sheet metal part, there are some things you should mind.

Types of Sheet Metal Parts

There are 3 main types of sheet metal parts.

- Flat Sheet Metal Parts

It generally refers to the plane blanking room, which is processed and produced by various blanking equipment. The cost is low, and it is widely used in some technical industries of sheet metal production and processing.

- Bent Sheet Metal Parts

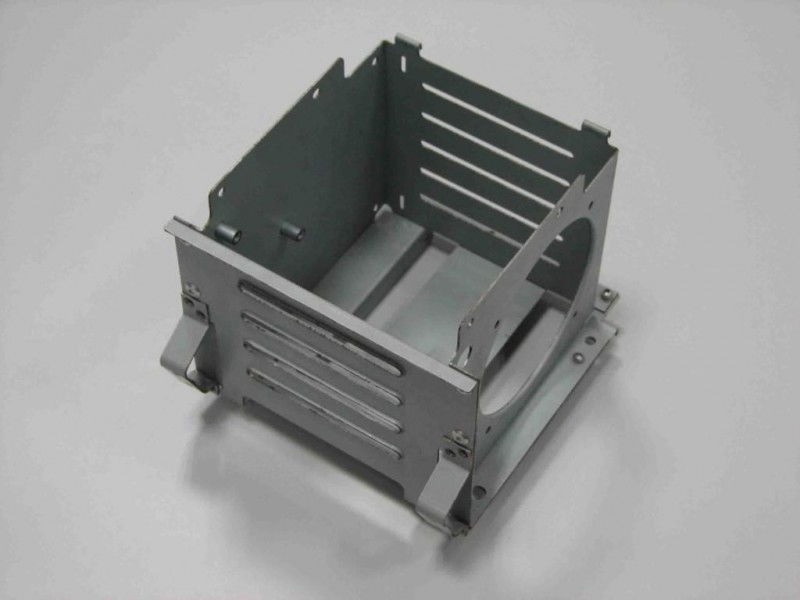

These are parts produced by bending. This type of sheet metal parts has diversified products and strong hardness. It is widely used in connecting parts and is also widely used in production industries with shape requirements.

- Forming Sheet Metal Parts

which are formed by stretching and other methods. Processed surface parts. The process of stamping and cutting is widely used.

Overview of Sheet-Metal Dies

In the small batch production of sheet metal parts, the simple die structure has been widely used. Stamping die is special process equipment that processes materials into parts that meet the requirements under the action of cold stamping. The punching die has the advantages of simple structure, convenient manufacture and low cost, and can meet the processing requirements of small sheet metal parts. In the stamping production of sheet metal parts, the die can be used to manufacture parts through processing operations such as blanking, punching, bending and drawing. It can be said that the rationality of die design plays a very important role in the quality of product processing, production efficiency and economic benefits.

How’s the Performance of Sheet Metal Fabrication?

Usually, there is a one-to-one correspondence between the stamping die and the stamping part, which is usually not universal, and is suitable for use in the processing of mass-produced parts. The process of punching is to design, process and form the raw materials, which have an “exactly the same” relationship with the parts required by the drawing. A mold with qualified quality not only requires the material selection of the mold parts to meet the performance requirements, but also needs to be processed with the parts. The pattern design requirements are consistent, and the quality of the assembled mold must meet the design quality, the quality of the test punching parts must meet the requirements, and the punching die must be of stable quality, good durability, and high product added value.

How to Scheme for Small Sheet Metal Parts?

The basic steps of the processing process of thin sheet metal parts are punching first, and then blanking.

The first process plan considered is to blank the material first, then punch the composite mold, and use a one-time forming process. After analysis, it is found that the small sheet metal parts produced by this plan are accurate in size, but because the small hole punch of this small sheet metal part is relatively long and prone to instability or bending.

If the process of punching small holes and then punching large holes is used after blanking, it is found that it is difficult to locate in the process of punching, and the dimensional accuracy is not high. Finally, the scheme of punching large holes first and punching small holes in the positioning holes based on the large holes is adopted. Compared with the first two process schemes, the accuracy of the first scheme is not as high as that of the first scheme, but its processing is stable. It has better performance and less impact on the mold, and the structure of the mold is relatively simple, the manufacturing is relatively fast, and the dimensional accuracy is also ideal.

Precaution of Small Sheet Metal Parts Fabrication

On the die structure of small sheet metal parts, each stamping unit is composed of upper and lower dies of each group. Each stamping unit is relatively independent. The stamping units of each step are arranged adjacently in sequence. During this period, the focus is on It should be noted that each station must be accurately positioned, which is very important to ensure the quality and accuracy of processing. Because the blanking has strong directionality, it is necessary to pay attention to the cavity type corresponding to the selection of the fixed plate of the punch, and as well the fixing for the concave die.

At JTR, we can support you with fine sheet metal fabrication manufacturing, our sheet metal has features of fast to operate so as to save time, convenient to fix so as to save money, for small sheet metal parts fabrication we can also show our strength on it, so if you are in need of products like this, you are welcome to consult with our engineering team.