CNC milling machines are currently instrumental in carrying out automated machining with high precision on intricate components for various industries like aerospace, automotive, etc. It is, however, the machine configuration axis that is most critical, as it determines the automated machining activity capability and precision in a given direction. Mastering the CNC axis is essential in maximizing the productivity and quality of the output. This article analyzes the most critical components of a CNC milling machine, its axes, the classification of the machine axes, the functions of machine motion, and the principles governing machine operation.

Part 1: What are CNC Milling Machine Axes?

The Axes of CNC milling machines comprise the directions in which the workpiece or the cutting tool is capable of moving. Each axis is a degree of freedom. The number of axes also reflects the complexity of shapes the machine can create without manual assistance. The movements are predefined in a computer program by means of G-Codes which outline the coordinates to be followed as well as the speeds, which enables them to operate in a fully automated, repeatable, and accurate manner.

Classification of CNC Milling Axes

The axes are broadly categorized into two types: linear axes and rotary axes.

Linear Axes (X, Y, Z)

The linear axes are straight line motions that can occur within a three dimensional space.

- X-axis: Controls horizontal movement, in general describes movement from left to right (or right to left).

- Y-axis: Controls movement from front to back, determines vertical position.

- Z-axis: Controls depth of tool movement, vertical movement in which the tool moves up and down (depth position is controlled).

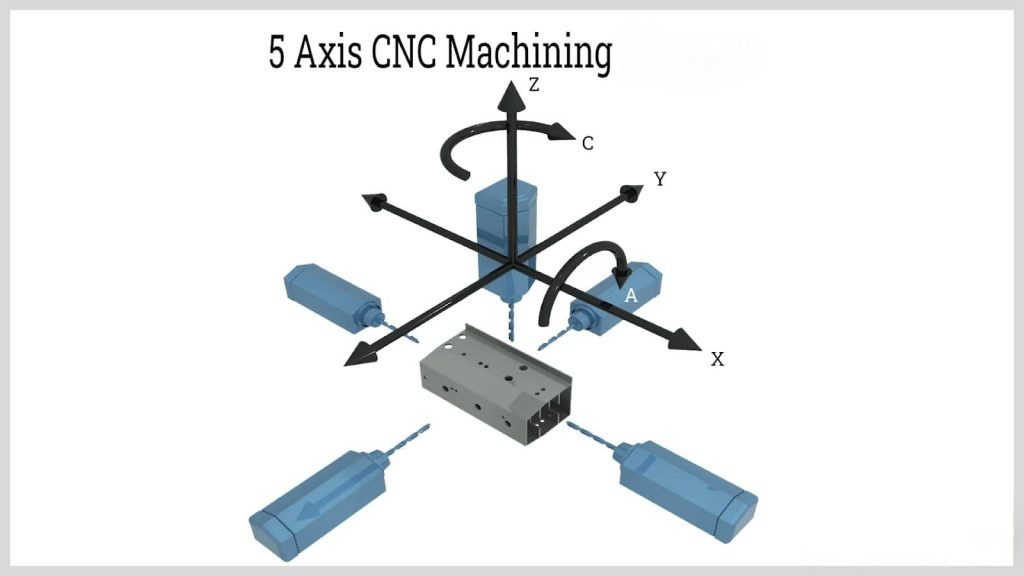

Rotary Axes (A, B, C)

The rotary axes add a spin, permitting the tool and workpiece to stand at a single angle and perform various rotations for addition to more advanced and complex machining.

- A-axis: Movement that revolves around the X axis, commonly used to pivot the workpiece forward and backward.

- B-axis: Movement that revolves around the Y axis, used to tilt a tool or workpiece for angled machining.

- C-axis: Movement that revolves around the Z axis, which allows position rotation of 360° or circular machining.

Part 2: How Do CNC Milling Machine Axes Work?

Operation of the CNC axes is a closed-loop, feedback system, monitored by a computer numerical control unit. A process like this can be broken down into four parts:

- Program Input: The first step is to create the G-code or M-code system. A program like this determines the tool paths, cutting parameters, and the type of movements the machine will do. The program is now uploaded to the CNC controller.

- Control System Literalization: The CNC controller transforms the program into electrical signals. The system then determines how each separate motor (servo or stepper) should be activated for each axis movement.

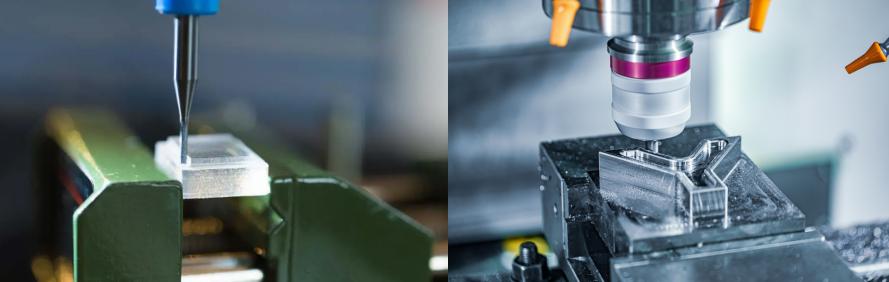

- Drive Execution: The servo drives and motors’ job is to execute that movement. They should accurately position the tool or the workpiece in relation to the programmed path. The movement of the tool is then guided by the ball screws and linear guides.

- Real Time Feedback and Correction: Encoders and sensors send feedback that helps the machine to comply with the axes speed and positioning. A machine is accurate if it is able to eliminate, on the programmed path, any inconsistencies in the path in real time.

The closed-loop feedback system is the reason why CNC machines have the ability to create parts with micron precision.

Part 3: Common CNC Milling Machine Axis Configurations

The combination of linear and rotary axes defines the machine’s type and its application scope.

| Type | Motion Axes | Features | Core Machining Capabilities | Typical Application Scenarios |

| 3-Axis Machining | X, Y, Z | The workpiece is fixed; the tool moves in three linear directions. | Machining from the top of the workpiece; capable of planes, slopes, cavities, and drilling. Only one side can be machined per setup. | Sheet metal parts, mold cores/cavities, mechanical components, prototyping. The most widely used, ideal for beginners. |

| 3+2 Axis Machining | X, Y, Z, A, B/C | Fundamentally a five axis machine, but the two rotary axes do not move at the same time. The workpiece has rotational tilting to a set angle and then proceeds in a 3 axis fashion wot. | Can machine five sides of a workpiece and complex angled features. Removes numerous manual setups, augmented precision and efficacy. | Box type components needing multi side machining, features at complex angles. An economic multi side machining answer. |

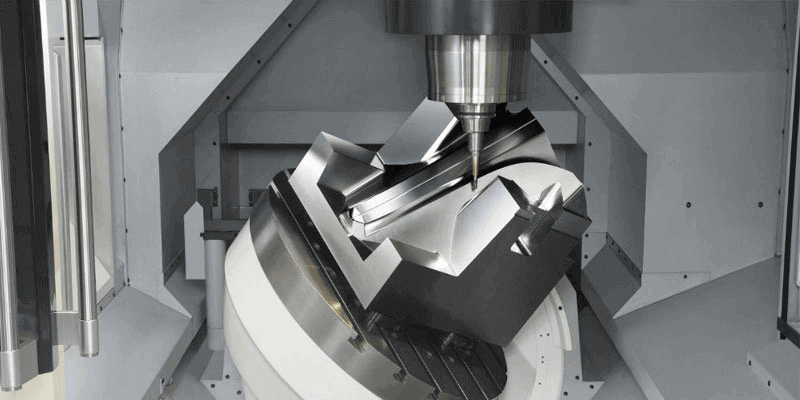

| 5-Axis Machining | X, Y, Z, A, B/C | All five axes can move at the same time and in a coordinated manner which allows the tool to reach the workpiece from any angle in space. | Machining of complex free-form surfaces such as impellers and turbines as well as artificial bones is possible. Use of shorter tools increases surface finish and efficiency. | Aerospace components, high-precision medical implants, complex automotive molds, impellers, military products. This is the peak of manufacturing capability. |

| 4-Axis Machining | X, Y, Z, A/C | Adds additioning one A rotary axis (usually A-axis around X or C-axis around Z) to the 3-axis base of the system. | Machining of cam surfaces (engraving) or the four lateral sides of a workpiece. | Cylindrical part machining, packaging machinery parts, 3D engraving on cylindrical surfaces. |

Wrap Up

Anyone in the field of precision manufacturing must learn about the axes of CNC milling machines. Each configuration, from the basic 3-axis to the more complex and expensive fully synchronized 5-axis, has its own set of advantages regarding intricacy, productivity, and cost. Automation, instant feedback in the form of software management, and computer-guided machines embedded into CNC milling technology have transitioned the approach to primary production – precision, repeatability, and extensive reach are now the industry standards.

Partnerships with capable manufacturers are important to innovators and other global enterprises hoping to utilize this technology. The CNC milling service industry in China stands at the forefront of technology and engineering, and offers, state-of-the-art techniques and competitive prices. Chinese machine shops have the latest technology for 3-axis machining for prototypes to 5-axis machining for aerospace components. Their advanced skills and equipment will produce exceptional outputs for your China CNC milling service. Their reliable supply chain offers high precision parts with a quick turnaround of your multifunctional components at any project scale. This makes CNC machining fabrication a wise decision.