In the hyper-competitive world of consumer electronics and industrial devices, the enclosure is no longer just a shell—it is your brand’s first impression, its structural integrity, and its thermal backbone. Whether your product is for industrial use, like an IoT sensor, a power controller, a medical instrument, or even the mobile phones we use in daily life, the right enclosure manufacturer determines not only how well your product is built, but also how fast it reaches the market.

As an experienced CNC machining and enclosure manufacturing company, JTR Machine understands the complexity behind creating high-precision housings for modern electronic devices. Below, we’ll guide you through the essential steps to choosing the right enclosure manufacturer that aligns with your project goals.

Step 1. Define Your Own Requirements

Before reaching out to potential manufacturers, you need a clear picture of your product’s technical and functional needs. The more specific your requirements are, the easier it is to find a capable partner.

1. Product Positioning

Start by clarifying the application scenario of your electronic device.

Is it a consumer-grade gadget, an industrial controller, or a medical diagnostic tool? Each category demands different levels of durability, heat dissipation, and EMC shielding. Consumer-grade products may focus more on appearance and cost, while industrial-grade and military-grade products have higher requirements for durability and reliability. For example, JTR provides custom aluminum enclosures for high-performance electronics that require superior thermal conductivity and structural strength.

2. Technical and Performance Requirements

Material Selection: Understanding the Differences

Different materials deliver different properties. Material selection not only affects product appearance, but also directly affects performance. Common options include:

| Material Type | Key Properties | Advantages | Limitations | Typical Applications |

| Aluminum Alloy (e.g., 6061, 7075) | High strength-to-weight ratio, excellent heat dissipation, corrosion resistance | Precise machining capability, premium look, excellent for CNC milling | Higher material cost than plastics, may require surface treatment | Industrial controllers, power modules, communication equipment, aerospace electronics |

| Stainless Steel (e.g., 304, 316) | Exceptional corrosion and chemical resistance, durable under extreme environments | High structural rigidity, ideal for harsh conditions | Heavier weight, more difficult to machine, higher cost | Outdoor devices, marine electronics, medical instruments |

| Magnesium Alloy | Very lightweight, good EMI shielding, strong rigidity | Ideal for portable devices requiring strength and low mass | Prone to corrosion if not coated, higher cost | Aerospace instruments, handheld devices, defense electronics |

| ABS Plastic | Lightweight, easy to mold, cost-effective | Excellent for mass production, good impact resistance | Limited thermal resistance, less durable than metals | Consumer electronics, IoT devices, smart home products |

| PC (Polycarbonate) | High impact strength, transparency, heat resistance | Electrical insulation, UV stability (with coating) | Prone to scratching, less rigid than aluminum | Power adapters, LED housings, control panels |

| Die-Cast Aluminum | Good dimensional stability, high EMI shielding, customizable shape | Economical for large volumes, strong and uniform surface | High tooling cost for low-volume runs | Automotive electronics, communication base stations |

| Composite Materials (e.g., ABS+PC blends, carbon fiber) | Tailored performance by mixing materials | Balance between strength, aesthetics, and weight | More complex manufacturing process | Premium consumer devices, high-end wearables |

Each material brings unique performance benefits depending on the device’s application environment, cost targets, and production volume. For instance, aluminum and stainless steel are ideal for industrial or outdoor enclosures, while ABS and PC remain top choices for consumer electronics.

JTR supports multi-material manufacturing, offering both plastic and metal enclosure fabrication. Our engineers assist clients in selecting the most suitable material, ensuring the best balance between cost, strength, and design needs.

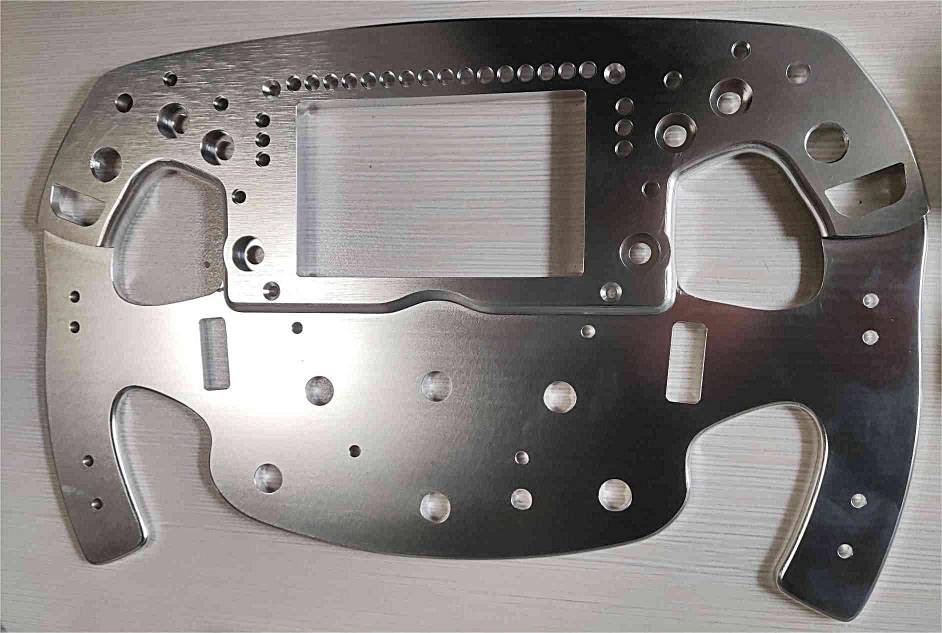

Design Complexity

If your design involves intricate geometries, tight tolerances, or integrated assemblies, you’ll need a manufacturer proficient in 5-axis CNC machining and custom tooling. JTR’s advanced equipment allows for complex enclosure production while maintaining ±0.01mm precision.

Protection Level

Consider your device’s required IP rating (Ingress Protection). For outdoor or industrial products, waterproof and dustproof sealing is critical. Manufacturers like JTR can incorporate gasket grooves, O-ring slots, and precision fits to achieve IP65–IP68 protection levels.

3. Compliance and Certifications

Electronics often need to meet international standards such as RoHS, REACH, or UL. Choose a manufacturer familiar with these certifications to ensure your enclosure materials and finishes meet global market requirements. JTR provides full material traceability and compliance documentation upon request.

Step 2. Evaluate Whether the Manufacturer Can Meet Your Requirements

Once your needs are defined, it’s time to evaluate whether a manufacturer can deliver the required quality and precision. Here are the key factors to consider.

1. Manufacturing Capabilities

Look for a partner with complete in-house production capacity, covering CNC machining, die casting, sheet metal fabrication, and surface treatment.

JTR’s factory is equipped with 3-, 4-, and 5-axis CNC centers, enabling one-stop production from prototype to mass manufacturing.

2. Material Expertise

Material knowledge is fundamental. Your supplier should understand not only how to process aluminum, steel, or plastic, but also how each reacts to temperature, coating, and machining speed.

At JTR, engineers provide material recommendations based on thermal conductivity, mechanical strength, and corrosion resistance, ensuring your enclosure performs under real-world conditions.

3. Surface Finishing Options

The surface treatment not only improves appearance but also extends product life. Common finishes include anodizing, powder coating, sandblasting, laser engraving, and screen printing for branding.

JTR offers kinds of finishing options, custom anodized colors and textures, helping your enclosures achieve both functional and aesthetic excellence.

4. Quality Assurance and Testing

A trustworthy manufacturer should maintain rigorous quality control at every production stage.

At JTR, every part undergoes dimensional inspection, surface roughness testing, and salt spray testing to ensure consistency and reliability. The company operates under ISO 9001:2015 certification, guaranteeing international quality standards.

5. Customization and Design Support

Strong engineering collaboration is key to turning a concept into a manufacturable product.

JTR’s OEM/ODM services include DFM (Design for Manufacturability) analysis, rapid prototyping, and engineering consultation, helping clients optimize designs for cost, performance, and production speed.

6. Communication and Delivery Efficiency

Smooth communication saves time and prevents costly misunderstandings.

JTR’s international project team provides English-language support, real-time progress updates, and fast lead times, ensuring your enclosures are delivered on schedule — from prototype to final assembly.

Step 3. Communication & Project Management

Even with the right capabilities, project success depends on how effectively you collaborate with the manufacturer. Clear collaboration helps prevent costly errors and ensures the final product meets your expectations in every detail.

1. Factory Visit: Seeing is Believing

Conducting a factory visit is one of the most effective ways to verify a manufacturer’s real capabilities. Seeing the production environment, equipment condition, and operator skills firsthand provides insights that no brochure or website can offer.

At JTR Machine, clients are encouraged to visit our production facilities — either in person or via an online factory tour. This transparency allows you to assess our machining centers, quality inspection process, and overall manufacturing culture before committing to large-scale production.

2. Requesting and Testing Samples

Requesting samples or prototypes is a critical step to validate whether a manufacturer can meet your quality and performance standards.

Before mass production, every sample should be tested for:

- Dimensional accuracy and assembly fit

- Material verification and mechanical strength

- Surface finish quality (e.g., anodizing, coating, engraving)

- Reliability testing such as drop, abrasion, or salt spray tests

JTR provides rapid CNC prototype machining and sample verification services, enabling clients to identify potential design or tolerance issues early — saving both time and cost during full-scale manufacturing.

3. Establishing Clear Communication Channels

A well-defined communication structure is the backbone of successful project execution.

Assign a dedicated project manager to act as the single point of contact, and agree on regular update intervals to ensure both sides stay aligned on progress, quality expectations, and any design revisions.

JTR maintains real-time communication through dedicated account managers and engineering liaisons. Weekly progress reports, milestone reviews, and virtual meetings help identify potential issues early and keep the project on track.

4. After-Sales Service and Long-Term Support

A responsible manufacturer’s commitment doesn’t end when production is complete. Evaluate their after-sales service, including warranty terms, technical support capabilities, and responsiveness to quality concerns.

At JTR, we provide comprehensive after-sales assistance, including rework options, spare parts machining, and engineering feedback for design improvements. This ongoing support reflects our philosophy — to be not just a supplier, but a long-term manufacturing partner that contributes to your product’s success in the market.

Final Thoughts: Why Chinese Manufacturers Excel in Electronic Enclosure Production

China’s manufacturing ecosystem offers unmatched advantages in the electronic enclosure industry — from material sourcing and cost efficiency to advanced machining technology and rapid logistics.

Manufacturers like JTR Machine combine precision CNC capability, flexible customization, and global communication experience, making them trusted partners for electronic brands and engineers worldwide.

The right enclosure manufacturer isn’t just a supplier — it’s a strategic partner who helps you transform your product idea into a reliable, market-ready reality.