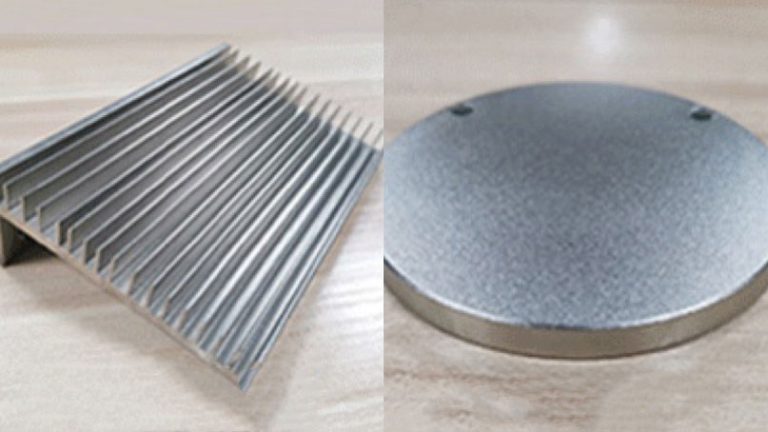

Aluminum alloy shell CNC machining surface treatment method

With the development of science and technology, people have put…

With the development of science and technology, people have put…

What is Aluminum Alloy? As a light metal material, aluminum…

This article will introduce the basic properties and applications of…

This article will introduce the commonly used mold surface finishing…

This article will introduce some common stainless steel surface finishing…

At present, the anodizing industry of plastics has achieved its large-scale…

In CNC surface finishing is a process to alter where the surface of the manufactured metal parts, and to achieve the level of desired appearance or surface texture. And there are various types of finishes each of them should match the unique situation. Such as mechanical, chemical, or electrical.

Request A Quote