What Are the Types of Powder Coating Materials?

Powder coating has become a popular choice for surface finishing in…

Powder coating has become a popular choice for surface finishing in…

Surface finishing plays a crucial role in various industries, providing protection,…

In the world of surface finishing, hard chrome plating stands…

Anodizing and chemical oxidation are both metal surface treatment services…

In the surface heat treatment process, because the names of…

First, understand the definitions of the two: What is Powder…

As we all know, electroplating is a process of plating a…

What is Electroless Plating? Electroless plating is also called autocatalytic plating….

Electroplating is the process of using the principle of electrolysis…

With the continuous development of material technology, plastic products are…

In the production of tires, the tire mold is one…

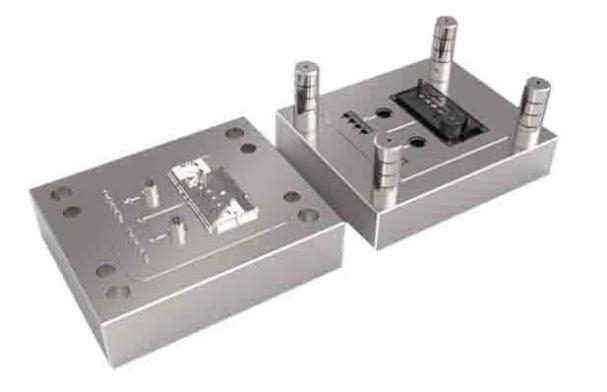

The performance of the mold will be affected by the…

Request A Quote