Can Anodizing Be Repaired?

Anodizing is an electrochemical process that transforms the surface of…

Anodizing is an electrochemical process that transforms the surface of…

Choosing the right finish for your project can be challenging….

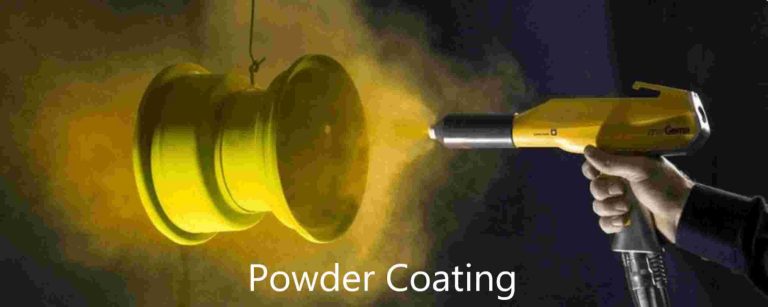

Powder coating is a type of dry finishing that uses…

Powder coating is a modern and popular dry-finishing technique that uses…

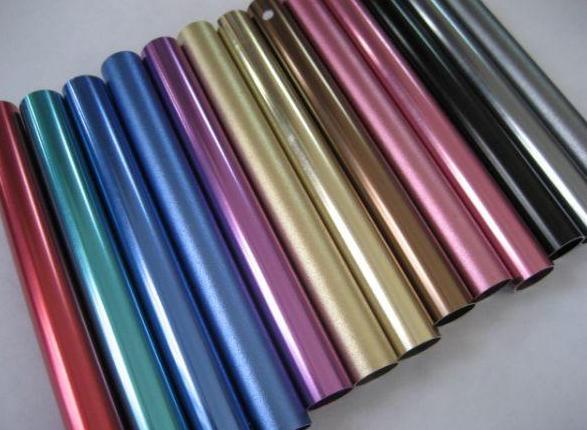

Anodizing is an electrochemical process that coats the surface of aluminum…

Anodized aluminum stands as a testament to the marriage of…

Stainless steel is a versatile and durable material known for…

Stainless steel is a versatile and popular material known for…

When it comes to the finishing touches in interior design,…

CNC bronze and brass machining are subtractive manufacturing processes that use…

Anodizing is a versatile and widely used surface treatment process that enhances…

Anodizing is a widely used surface treatment process that enhances the…

Request A Quote