The automotive industry is one of the most demanding and competitive industries in the world. Automakers are constantly striving to develop new and innovative vehicles that are more fuel-efficient, safer, and more affordable. To meet these challenges, automakers rely on a wide range of materials, including stainless steel.

Stainless steel pins are an vital component in the auto industry. They are used in a wide variety of applications, from engine components to body and trim components. Stainless steel pins are chosen for these applications because they offer a number of advantages. In this article, we will explore the type of Stainless steel to make Stainless steel pins and how it benefits for automotive industry.

What are the different grades of stainless steel used for pins?

The most common grades of stainless steel used for stainless steel pins in the auto industry are:

- Grade 304 (AISI 304): This is the most common grade of stainless steel and is known for its good corrosion resistance and workability. It is often used for pins in general-purpose automotive applications.

- Grade 316 (AISI 316): This grade of stainless steel has a higher molybdenum content than Grade 304, which gives it improved corrosion resistance, especially to chlorides. It is often used for pins in applications where exposure to salt water or other corrosive chemicals is a concern.

- Grade 17-4 PH (AISI 630): This grade of stainless steel is known for its high strength and hardness. It is often used for pins in applications where high strength and durability are required, such as in engine and transmission components.

Other grades of stainless steel may be used for specific applications, depending on the required properties of the pin. For example, Grade 430 stainless steel is sometimes used for pins in low-cost applications, but it is not as corrosion-resistant as Grade 304 or 316.

The selection of the appropriate grade of stainless steel for a particular application depends on a number of factors, including the required strength, corrosion resistance, wear resistance, and cost.

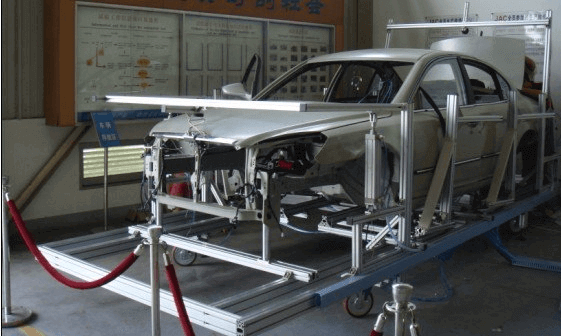

Specific Application of Stainless Steel Pins in the Auto Industry

Stainless steel pins are used in a variety of applications, including:

- Engine components: Stainless steel pins are used in various engine components, such as pistons, connecting rods, and camshafts. They help to secure these critical components in place and prevent them from wearing down over time.

- Transmission components: Stainless steel pins are also used in various transmission components, such as gears, shafts, and bearings. They help to reduce friction and wear and extend the life of the transmission.

- Suspension and steering components: Stainless steel pins are used in various suspension and steering components, such as ball joints, tie rods, and control arms. They help to keep the vehicle’s suspension and steering systems aligned and operating smoothly.

- Body and trim components: Stainless steel pins are also used in various body and trim components, such as bumpers, grilles, and headlights. They help to attach these components to the vehicle’s body and ensure a secure fit.

Here are some specific examples of how stainless steel pins are used in the automotive industry:

- Cotter pins: Cotter pins are used to secure nuts and bolts in place. They are often used in applications where the fastener is subject to vibration or shock.

- Dowel pins: Dowel pins are used to align and position two or more components. They are often used in applications where high precision is required.

- Spring pins: Spring pins are used to secure two or more components together. They are often used in applications where the components need to be able to move relative to each other.

- Circlips: Circlips are used to retain shafts and bearings in place. They are often used in applications where the components are subject to high rotational speeds.

Stainless steel pins are also used in a variety of other automotive applications, such as electrical systems, exhaust systems, and climate control systems.

Benefits of Using Stainless Steel Pins in the Automotive Industry

Stainless steel pins offer a number of benefits for the automotive industry, including:

- High strength and durability: Stainless steel pins are very strong and durable, making them ideal for use in demanding automotive applications.

- Corrosion resistance: Stainless steel pins are highly resistant to corrosion, which makes them ideal for use in harsh automotive environments.

- Wear resistance: Stainless steel pins are also highly resistant to wear, which helps to extend the life of automotive components.

- Ease of use: Stainless steel pins are easy to install and remove, which reduces assembly and maintenance time.

Conclusion

Stainless steel pins are an essential component of the automotive industry. They are used in a variety of applications to secure, align, and position automotive components. Stainless steel pins offer a number of benefits, including high strength, durability, corrosion resistance, wear resistance, and ease of use. As the auto industry continues to evolve and become more demanding, stainless steel pins are likely to play an even greater role in the future.